Ascent AM – Adding Simulation to the corporate environment for additive manufacturing

The aim of the research project Ascent AM is the development of a simulation tool with which the additive production process of e.g. engine components can be analyzed and improved. The project is being funded within the framework of the European "CleanSky 2" network, which aims at increasing resource efficiency in aviation.

Motivation

In the future, a further increase in global air traffic is expected, which will be accompanied by an overall increase in pollutant emissions. In order to achieve a reduction in operating costs in addition to reducing environmental pollution, the development of new lowconsumption engines is one possible solution. To this end, lighter engine parts can contribute substantially. In order to reduce the mass of the components while at the same time ensuring the required properties, complex structures are required that are typically hard to manufacture. With the radiation melting technologies gaining ground however, more and more freedom of design can be achieved.

Objective

In the case of metalbased additive manufacturing processes, a large number of factors determine the process reliability as well as the component quality. Therefore, in current practice the way to a satisfying manufacturing result is often characterized by time- and resourceintensive experiments. In order to achieve a production of the propulsion components with minimal rejects and without the need for complex, previous test series, a simulation tool is to be developed that can improve the production process of the actual production costeffectively and save additional time. This can be done, for example, by adapting process parameters for a specific component area based on an analysis of the temperature field.

Procedure

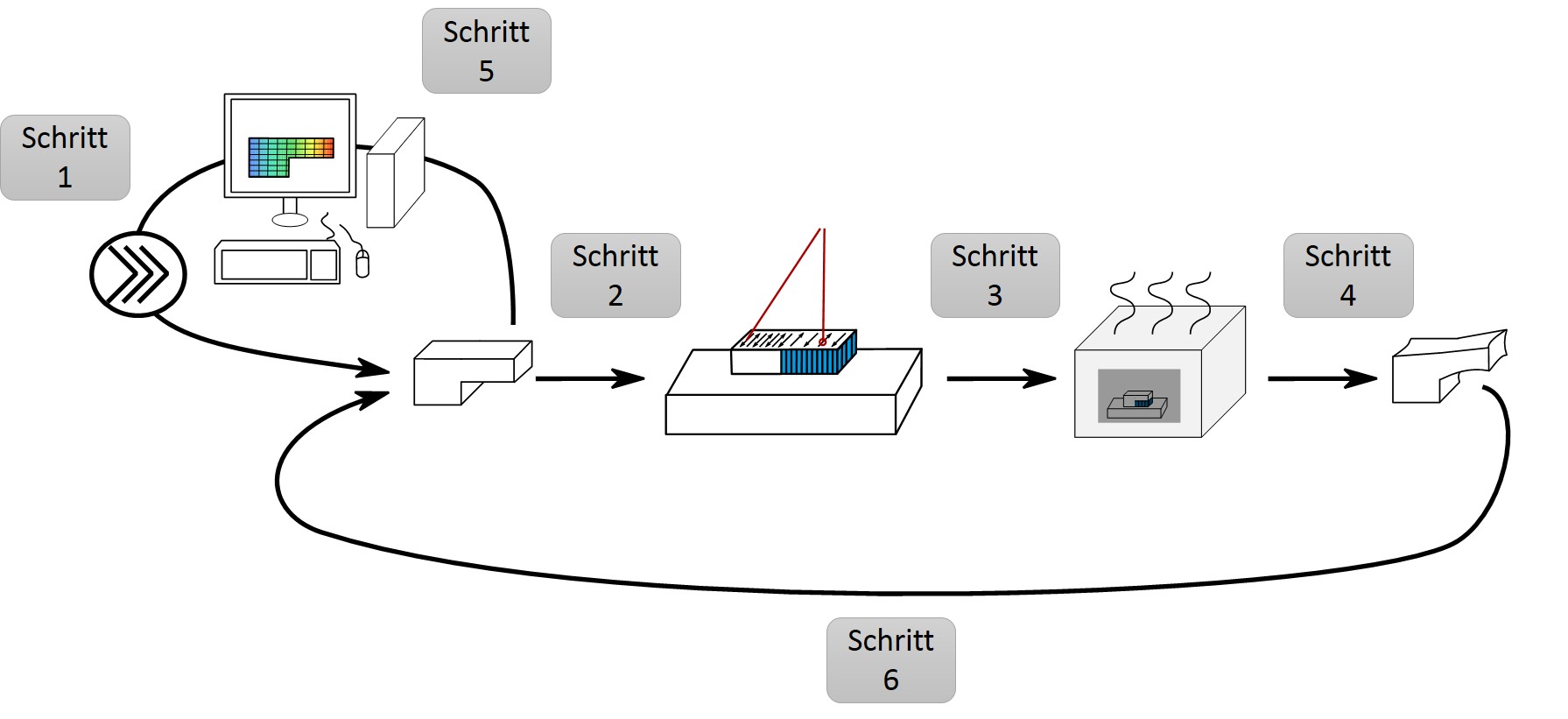

Initially, a computationally efficient component simulation of an additive production process is attempted by means of a simulation solution based on open source software. A suitable predeformation of the component on the basis of CAD data for the production process is to be calculated in order to adapt the original component geometry to the respective process in such a way that the predefined tolerances are reached after production. The software developed in this way has the advantage that it allows a wide use without excessive licensing costs. Iterative simulation steps adapt the resulting component geometry of the simulated production process until the best possible target geometry results. The resulting preformed component geometry is transferred and produced in the respective plant.

Results

Within the framework of this research project, a simulation tool is to be developed, which is capable of mapping all process steps of a real production process. The tool is intended to calculate temperature fields occurring in the component and the resulting deformations as well as residual stresses with sufficient accuracy. Furthermore, a simulationbased optimization is implemented, which is based on the data of the dimensional deviations. Exposure strategies as well as stress relieving of the component are taken into account. The resulting deformations of the component should be specifically calculated and returned to the original component. The entire calculation model is to be developed in an opensource environment and used in the aerospace and engine industry. Furthermore, the simulation tool is to be actively established in the development process of a company in the aerospace industry. Suitable training courses are offered.

Acknowledgments

This project has been financed by the "Clean Sky 2 Joint Undertaking", which was initiated under the Horizon 2020 Research and Innovation Program under grant agreement No. 714246.