Quality Assurance in PBF-LB/P

Process monitoring systems are not used in state-of-the-art laser-based powder bed fusion of plastics (PBF-LB/P) yet. In the research field “Quality Assurance in PBF-LB/P“, different process monitoring systems are utilized to enable an in-line qualification of new powders materials.

Aim

In state-of-the-art PBF-LB/P, the process parameters are usually defined beforehand and kept constant throughout the entire process. Hereby, components are only produced in sufficient quality if the material properties, part geometries, and process parameters are chosen appropriately. This in turn presupposes a profound process understanding and results in extensive parameter studies. Therefore, the aim of this research field is divided in:

- Determination of ideal processing conditions of new powder materials during processing

- Identification of correlations between critical process phenomena and part properties

- Increase of the available material spectrum and the reproducibility of part properties

Methodology

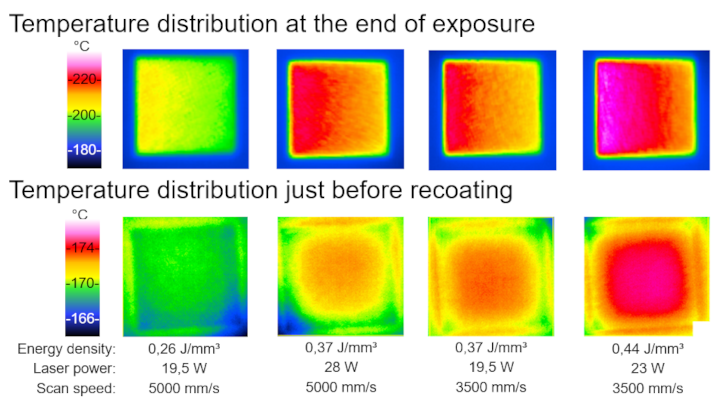

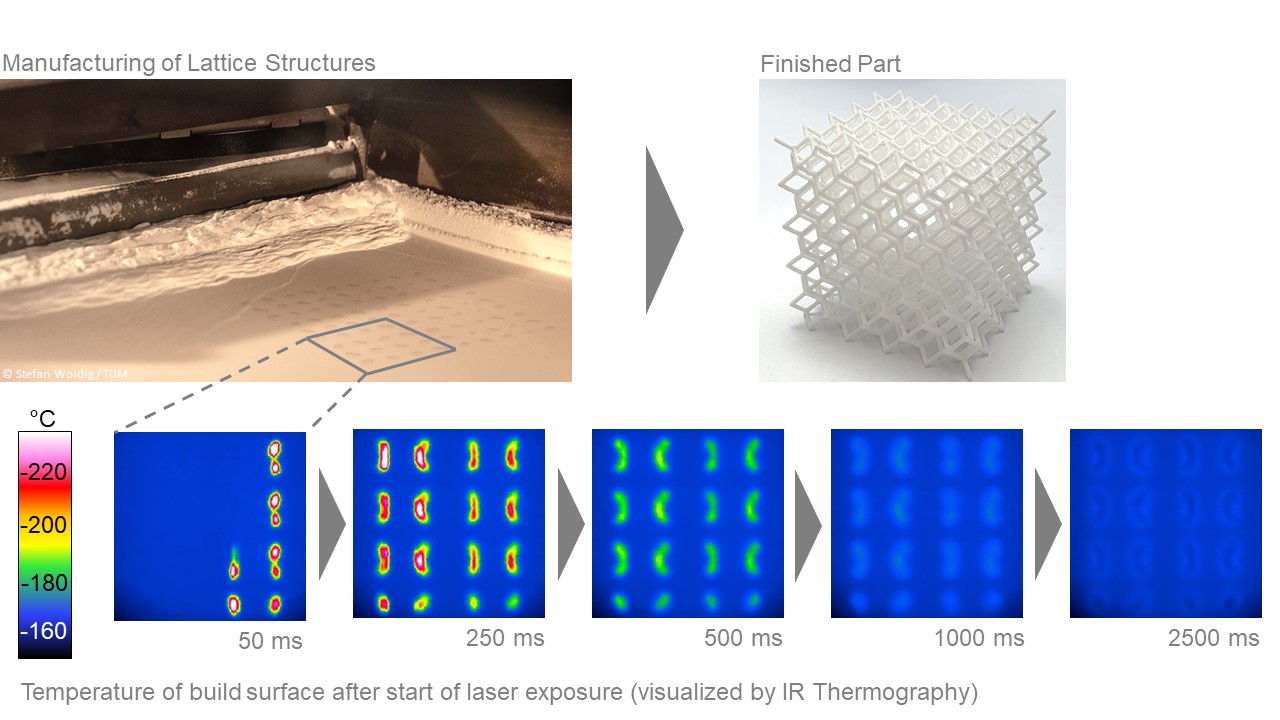

To achieve the goals described above, the geometry and the temperature during processing are paramount since both intermediate process variables determine the subsequent component properties. Therefore, the PBF-LB/P systems will be equipped with monitoring systems such as a high-resolution digital camera or a high-speed IR camera. Based on the respective process influencing factors, the measured intermediate process variables are correlated with the resulting component parameters.

Vision

After correlations between process data and part properties are identified, monitoring systems can be integrated into the process control to enable the detection of product defects or the prediction of corresponding part properties with machine learning algorithms.