News

Successful completion of the EFB project "Reduction of edge crack sensitivity by two-stage shear-cutting"

Content of the project:

The sensitivity of shear-cut component edges to edge cracking confronts the sheet metal processing industry with major challenges. Edge cracks occurring in the manufacturing process reduce the profitability and process stability to a high degree.

In this context, two-stage shear cutting represents a precision cutting process which makes it possible to significantly increase the residual forming capacity at the shear cut edge by simple, cost-effective adjustments in the tool and thus to reduce the tendency to edge cracking.

However, in order to maximize the potential of the two-stage shear cutting process, it is necessary to adjust the process parameters to the given cutting line geometry, the sheet material and the sheet thickness.

Within the research project, practice-oriented multidimensional regression models were developed for the dual-phase steel DP800 as well as for the stainless steel 1.4301 on the basis of experimental data. These enable the selection of a process window which allows components to be manufactured reliably even when wear is taken into account.

The regression models also offer the possibility of estimating the residual deformation capacity already in the simulative design process and of defining appropriate two-stage shear cutting parameters for critical areas in order to secure components at an early stage with regard to the development of edge cracks.

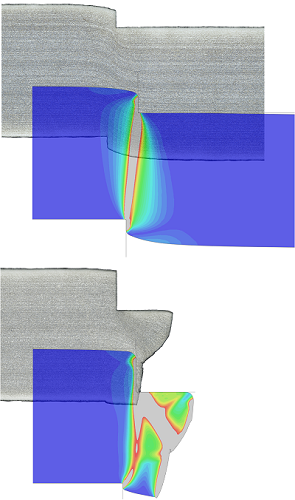

Furthermore, a simulation model was developed which can virtually reproduce a two-stage shear cutting process with very high accuracy. The characteristics of the shear affected zone were described using different parameters for quantitative comparison of the process parameter variations.

The comparison of the experimentally and simulatively determined results led to the formation of correlations, which now make it possible to determine adapted two-stage shear cutting parameters with the aid of finite element simulation without a high level of experimental effort.

Funding reference

The IGF project "Reduction of edge crack sensitivity by recutting" of the research association EFB e.V. was funded by the German Federal Ministry for Economic Affairs and Energy under the funding number AiF 19978N via the German Federation of Industrial Research Associations (AiF) within the framework of the program for the promotion of joint industrial research (IGF) based on a resolution of the German Bundestag.

The final report has been published as EFB Research Report No. 562 and is available at the EFB office and in bookshops (only in german language available).

Contact: Dipl.-Ing. Isabella Pätzold