The Learning Factory for Lean Manufacturing

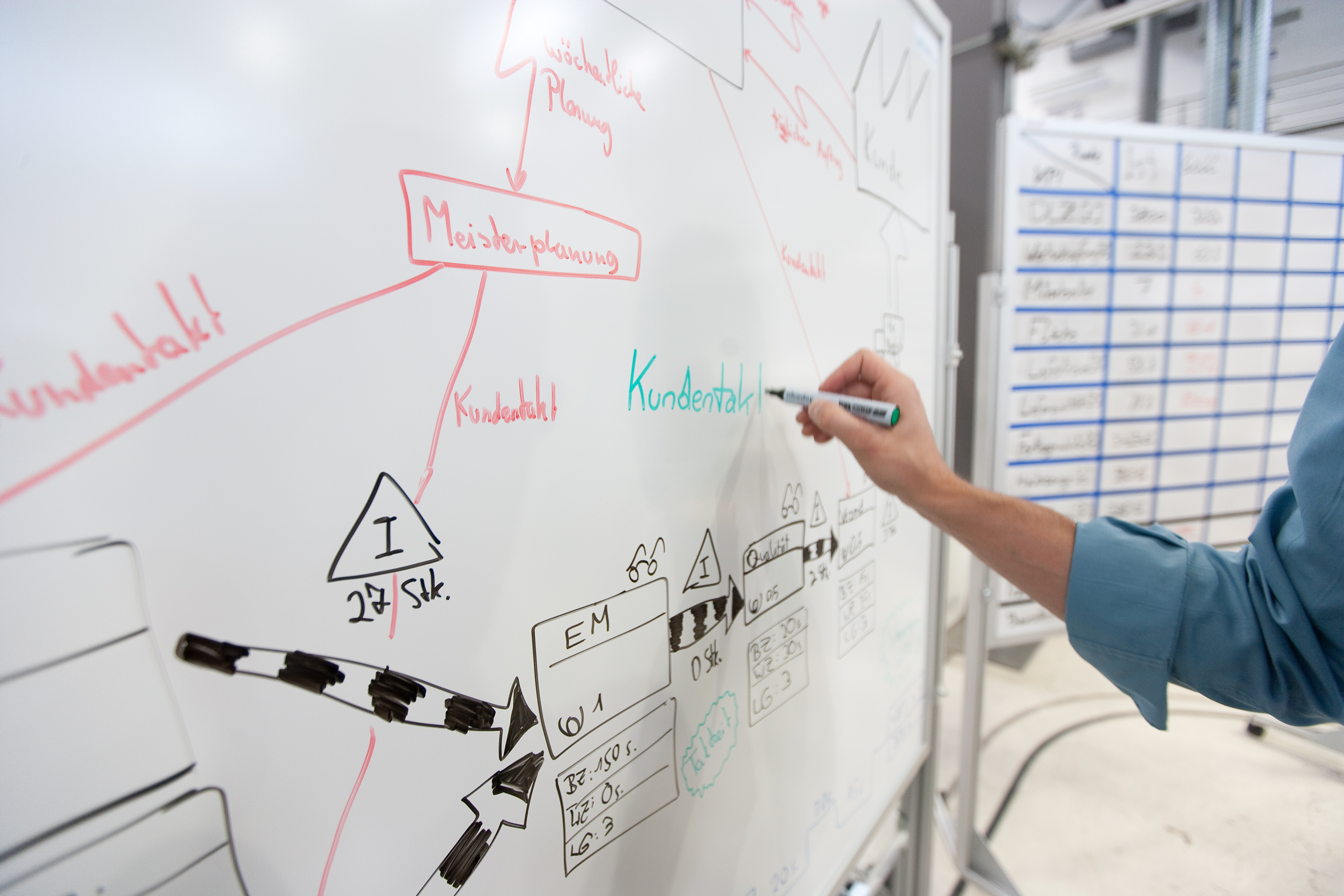

The Learning Factory for Lean Manufacturing (LSP) at the Institute for Machine Tools and Industrial Management (iwb) is a flexible, modular assembly system that supports the realization of various production structures, from classical workshop production to synchronized flow assembly, as well as various material supply strategies. Training participants test the principles and methods of lean manufacturing by assembling real, industrially used planetary gears.

Goals of Lean Manufacturing

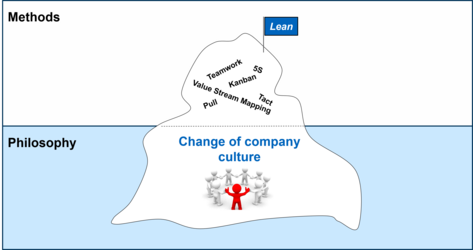

At the beginning of the nineties, the publication of the book "The Machine That Changed The World" marked a radical change in production thinking - the goal of maximum capacity utilization was replaced by striving for short lead times and avoiding waste. The ideas of lean production began their triumphal march in the industry - the practical success of implementation, however, still too often not achieved.

The Learning Factory's Contribution to Lean Manufacturing

As a guide to successful implementation, the LSP combines the teaching of theoretical principles with practical testing in a real production environment and directly addresses the main causes of inadequate implementation of lean production in industrial companies:

- Sensitization for waste and customer orientation

- Risk-free testing of lean production concepts in a real production environment

- Visualization of boundary conditions, impacts and interaction of methods

The training participants are thus not only provided with the necessary knowledge and a toolbox of methods, but are also able to experience lean production and its design.

We offer individual trainings

Individual training courses can be designed based on the modular training concept. Our focus is on the needs and requirements of the respective company. We offer you the entire spectrum from intensive courses (1-3 days) to two-week complete training courses - on request also at your production site. Our advantages are the complete integration of theory and practice as well as the mobility of our entire learning factory.