FOMIPU - Implant and Minimally Invasive Surgical Technique for Conversion Osteotomy in Children

Motivation

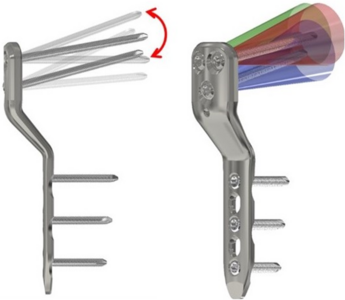

Hip joint diseases in children occur rarely and are also very different in their severity. In extremely severe cases, the children are no longer able to walk. A treatment method is the surgical correction of the deformity, a so-called conversion osteotomy with subsequent immobilization of the leg. The aim of a conversion osteotomy of the thigh is the three-dimensional alignment of the femoral head and shaft with subsequent fixation in the desired anatomical position by means of an implant (Fig. 1). The implants currently available on the market require preoperative planning, an invasive procedure and intraoperative visualization as well as a postoperative position check using X-ray diagnostics. Sometimes the correction of the femur cannot be implemented as planned due to the difficulty of estimating the correction angle despite intraoperative fluoroscopy. Translated with www.DeepL.com/Translator

Objective

The aim of the research project FOMIPU is the development of an implant and a minimally invasive surgical technique for osteotomy in children. In contrast to pre-vious surgical techniques, in which prefabricated implants are used, the use of a simulation-based optimization method and automatic individualization enables adaptation to the patient.

Procedure

The first step is to design an initial implant design with the corresponding target instruments for polyaxial screws (Fig. 2). On the one hand, this should be tailor-made for the patient and, on the other hand, it should give the physician the possi-bility of adapting to the respective surgical situation in order to ensure the best possible fit of the screws in the bone. These two initial design drafts are adapted to the later load cases with the help of a simulation-based optimization. For example, the reduction of the implant volume with sufficient stiffness can be selected as the objective function of the optimization. Two manufacturing process chains can be used to ensure patient-specific care. In the course of the project, conventional ma-nufacturing will be investigated using 5-axis simultaneous milling and additive ma-nufacturing of the components. Here it is important to consider and compare the design possibilities of the machining production or additive production already in the design process. The component quality and the economic efficiency of the ma-nufacturing process are considered as comparison criteria. The final quality tests carried out by iwb on conventionally and additively manufactured test specimens and components are aimed at the implementation of a certifiable and economical manufacture of the implants.