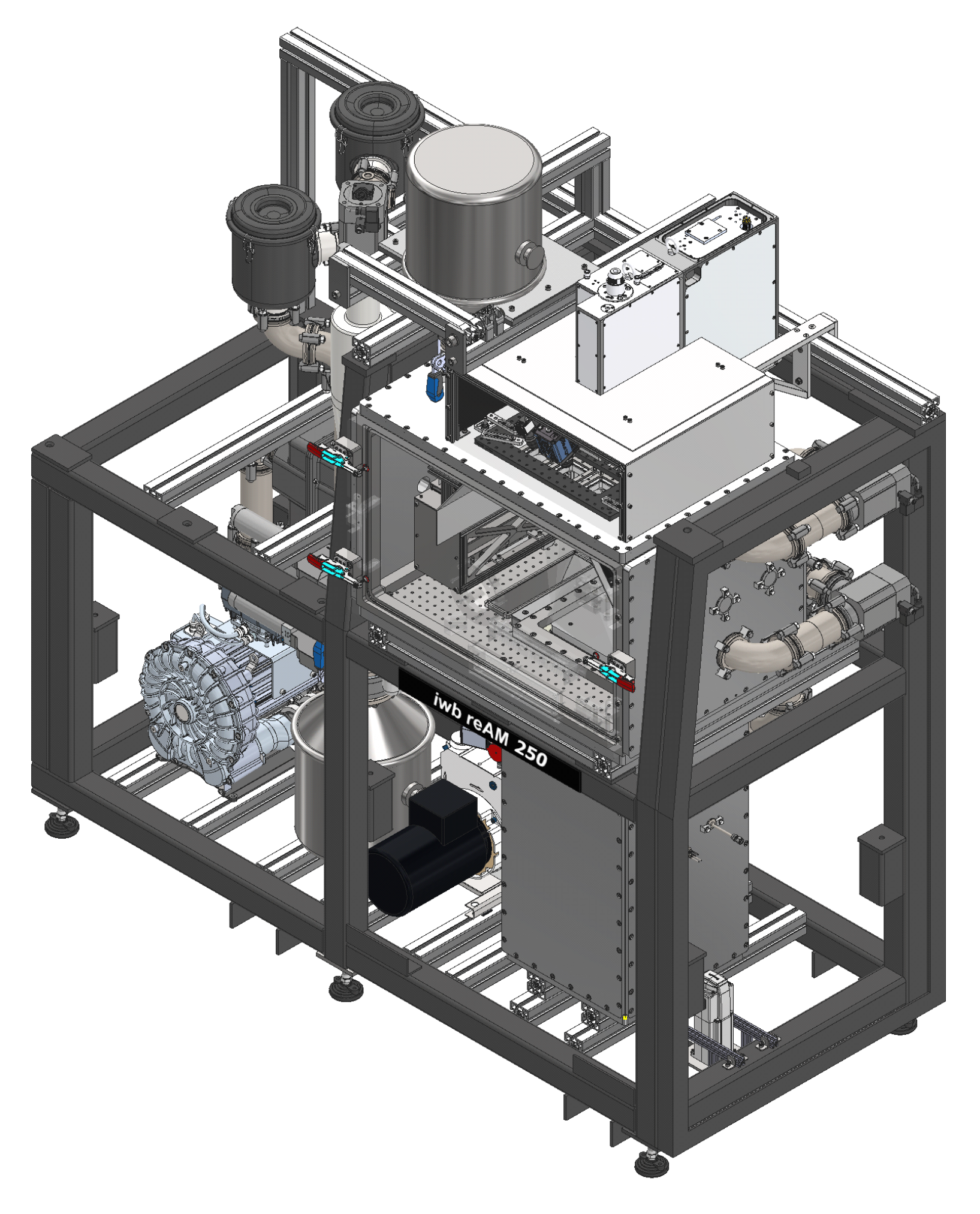

iwb reAM 250 – Powder bed fusion machine for research purposes

The iwb reAM 250 is an innovative powder bed fusion machine developed for research purposes at the Institute for Machine Tools and Industrial Management (iwb). In close cooperation with industrial partners, current research topics in the fields of the inert gas flow management, the powder recoating, and the system control are being pursued. The objective of the project is to provide a full-scale, state-of-the-art system under an open source license to the additive manufacturing community.

Initial situation

In the department of Additive Manufacturing at the iwb, powder bed fusion of metals using a laser beam (PBF-LB/M) is investigated simulatively and experimentally. Several industrial systems are available for this purpose. However, these commercial systems are designed for serial applications and therefore offer only limited accessibility as well as adaptability for specific process investigations. Therefore, an in-house PBF-LB/M machine is set up for future research activities. The open and modular design of this system is intended to offer various possibilities for basic and applied research.

Objective and expected results

The research machine iwb reAM 250 provides a full-scale system for the PBF-LB/M process under an open source license to the additive manufacturing community. The individual components exceed the current state of the art. A modular system design and good accessibility of the components enable the continuous improvement of the system. This allows for a convenient exchange of components and the integration of further innovative modules. Due to this intelligent design, the research machine opens up extensive monitoring opportunities at all process levels.

Approach

For the development of the iwb reAM 250, an innovative machine concept is drafted for the rough planning. This is followed by a detailed planning of the individual components, such as the vacuum-capable process chamber, the non-contact recoater, or the process gas system including a cyclone separator. Within the scope of teaching projects and student theses, the planning of the functional principle, the design, and the manufacturing of the individual components are carried out. The cooperation between students, research associates, and industrial partners provides a valuable contribution to the holistic teaching at the iwb. The system control is implemented via a machine control framework, which ensures a complete documentation of all system states. After setting up the individual components, the overall system is validated by the additive manufacturing of industry-relevant components. By this, the functionality of the iwb reAM 250 is proven.

Acknowledgements

We would like to thank all project partners for their excellent cooperation and all participating students for their active support.