PROLEI – Process chain for the joining of continuous-fiber reinforced plastics with metals in lightweight structures

Motivation

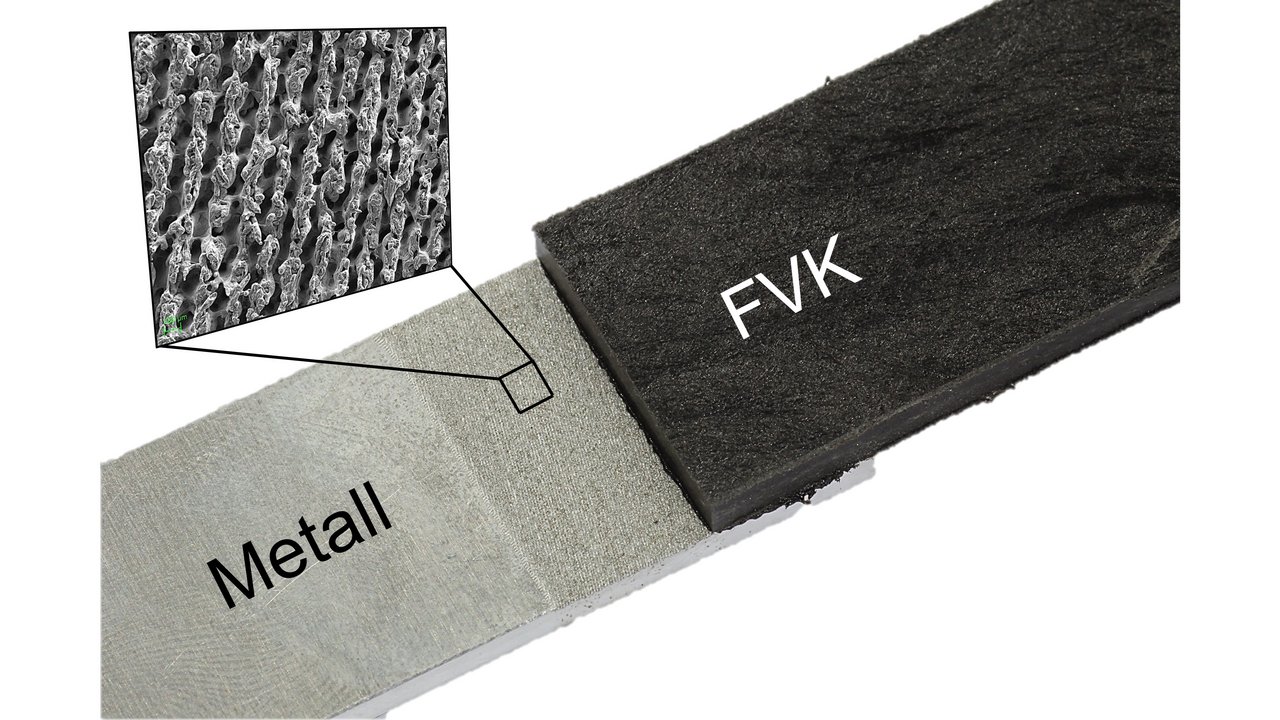

Today, vehicle bodies are predominantly designed in metallic construction. On load-bearing and safety-relevant car body segments, the all-metal construction can be replaced with a combinations of fiber-reinforced plastics (FRP) and metals. This enables a considerable potential for mass reduction. In this context, the directional load-bearing capacity of the FRP can be used specifically for improving the stiffness or the crash behavior. Such metal-plastic material combinations require special pre-treatment of the contact surfaces.

Objective and approach

Therefore, in the PROLEI research project, plastic-metal hybrid joints are qualified for industrial serial production. Within this context, novel joining technologies have to be developed. Thematic focuses are the processes for the laser-based structuring of contact surfaces and the automated execution of the joining process. The development of suitable production and automation technology is a requirement for direct use in industrial production process chains.

Acknowledgement

This research and development project is funded by the German Federal Ministry of Education and Research (BMBF) within the Program “Innovations for Tomorrow’s Production, Services, and Work” (funding numbers 02P16Z000 – 02P16Z005) and managed by the Project Management Agency Karlsruhe (PTKA). The author is responsible for the contents of this publication.

| Duration | 01.09.2016 bis 31.08.2019 |

| Project partner | Airbus Group Innovations, Arges GmbH, inpro Innovationsgesellschaft für fortgeschrittene Produktionssysteme in der Fahrzeugindustrie mbH, Technische Universität München (Institut für Werkzeugmaschinen und Betriebswissenschaften), Universität Paderborn (Laboratorium für Werkstoff- und Fügetechnik), Volkswagen AG |

| Funded by | German Federal Ministry of Education and Research (BMBF) |