Tramik - Trajectory Planning to increase the Dynamics of Laser Material Processing Manufacturing Processes

Motivation:

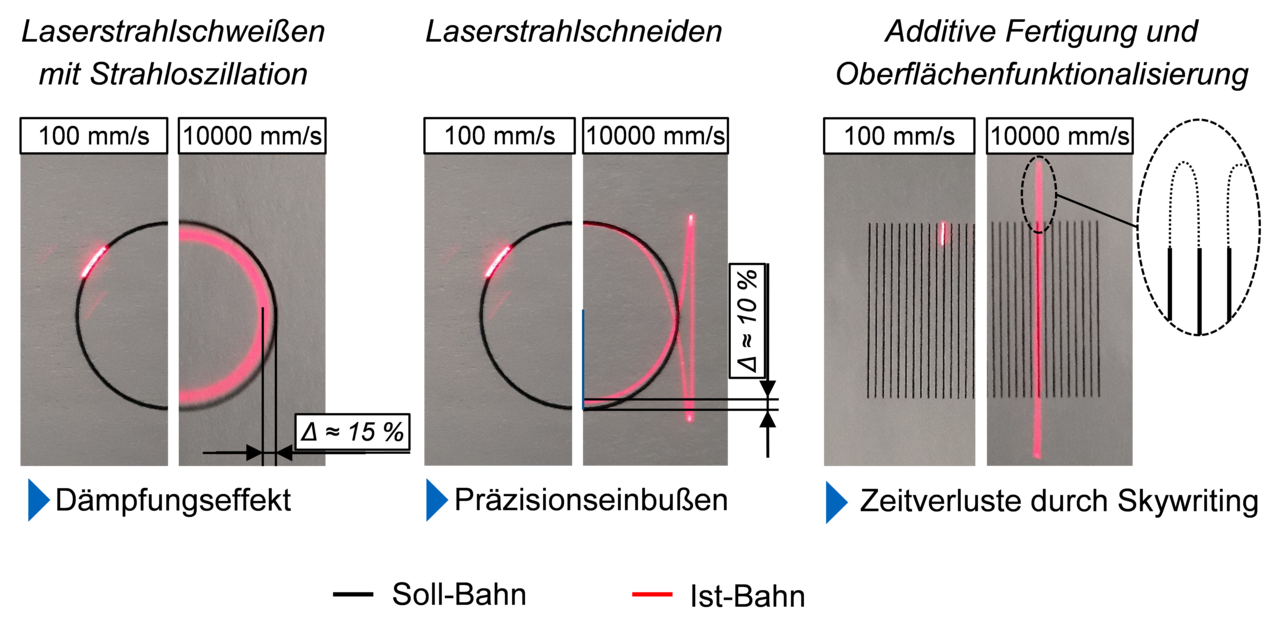

The combination of modern beam deflection systems, such as galvanometrically driven scanner optics, with innovative laser beam sources leads to a continuous expansion of application fields in both micro- and macro-material processing and enables productive and high-precision manufacturing. The system dynamics of laser systems represent a central building block for the industrial success of laser processes, but often do not yet meet the process requirements. This results in technical and economic limitations of the industrial use of the manufacturing processes leads. In addition, the application-specific parameterization of laser systems requires extensive expert knowledge.

Objectives and procedure:

The Tramik research project addresses the area of conflict between the productivity of manufacturing processes, the quality of processing results and the ease of use of laser systems by considering the individual aspects and their interactions. The solution approach provides for the development of a system-independent software module for autonomous trajectory planning, which predicts the movement of the laser focal spot on the workpiece based on a model and optimizes it according to the process requirements. The dynamics and accuracy of the system are improved by taking into account the characteristics of the scanner optics, the beam source, and the process characteristics of different laser methods. Exploiting the temporal modulation of the emission from the beam source and tuning the emission to the movement of the laser focal spot and the current process state is expected to improve the processing quality. The development of suitable communication protocols for synchronization of the laser beam source and scanner optics will contribute to this. The system complexity will be made manageable for the applying companies by a man-machine interface, which will enable process design without expert knowledge and by prioritizing different process requirements.

The Tramik project thus not only provides for a technical advancement of the system technology, but also addresses the overcoming of innovation hurdles through the application-friendly consideration of requirements during process design. In this way, the project is aimed at the growing importance of laser technology in industrial applications and supports companies in being able to manufacture new products more economically and resource-efficiently in the long term.