ASSISTANT - Learning and robust decision support systems for agile manufacturing environments

The EU-funded ASSISTANT project aims to develop breakthrough solutions for the manufacturing industry, using artificial intelligence to optimize production systems. One of the keystones of ASSISTANT is the creation of intelligent digital twins. By combining machine learning, optimization, simulation, and domain models, ASSISTANT develops tools and solutions providing all required information to help production managers design production lines, plan production, and improve machine settings for effective and sustainable decisions that guarantee product quality and safety.

Motivation

While artificiaI intelligence (AI) is already a reality for Google, Apple, Facebook, and Amazon (GAFA), it is not yet applicable to manufacturing industrial players. The GAFAs are using AI to deliver services to a large public, but manufacturers’ business models and needs are quite different: They address small markets with dedicated products, which require specialized digital twins for predictive and prescriptive analytics. Nevertheless, the potential of AI is clear: companies that embrace AI over the years may double their cash flows.

Objectives

With 12 Partners involved, ASSISTANT aims to provide a set of AI-based intelligent digital twins that helps process engineers and production planners to operate collaborative mixed-model assembly lines based on the data collected from IoT devices and external data sources. Such a tool will help planners to design the assembly line, plan the production, operate the line, and improve process tuning. In addition, the system monitors the line in real-time, ensures that all required resources are available, and allow fast re-planning when necessary. ASSISTANT aims to make cost-effective decisions while ensuring product quality, safety, the well-being of the workers, and managing the various sources of uncertainties. The resulting intelligent digital twin systems will be data-driven, agile, autonomous, collaborative, explainable, safe, and reactive.

Concept

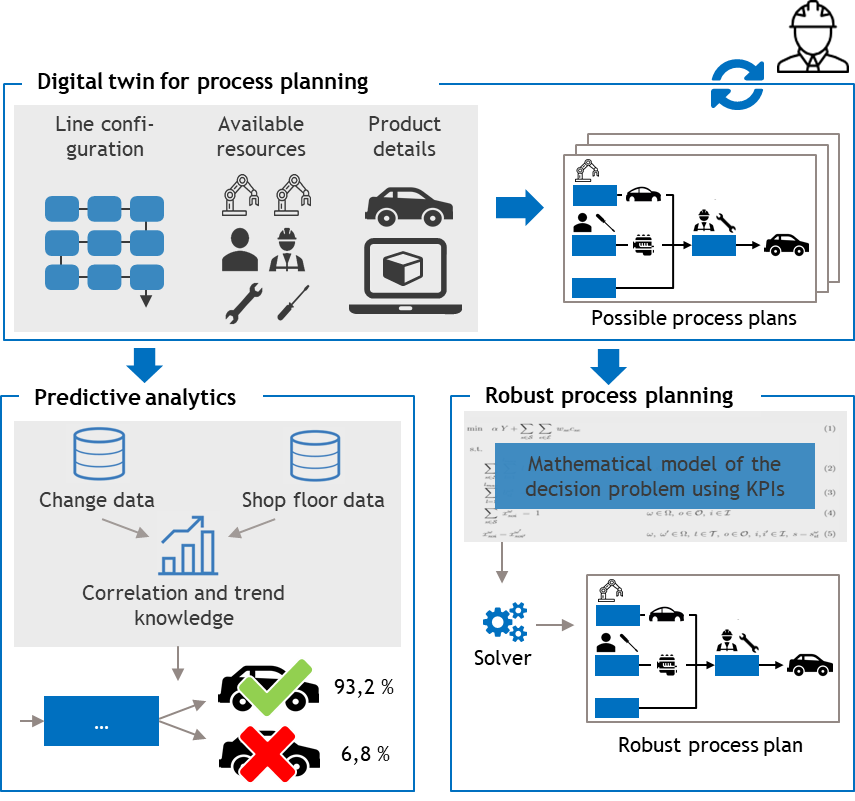

The architecture of the intelligent digital twin networks follows the three-step framework (perception, reasoning, actuation) provided in the AI definition of the European Commission. First, the data are perceived from sensors in the factory and external sources, and this creates a real-time digital image of the factory. Second, the reasoning step includes the three decision models (process planning/production planning/scheduling) built from the real-time image of the factory, as well as advanced prescriptive analytics techniques to create the plans that can be validated through simulation. The plan is then executed through a real-time control module.

iwb participates in the project in the development of a data-oriented digital twin for the planning of production processes. Using a digital representation of the production line and its resources, the digital twin predicts the product and process quality, concludes the impact of product and process changes, and designs process plans which fulfill predefined KPIs. The digital twin for process planning identifies possible process plans and includes visualization and inspection techniques for various production roles (e.g. process planer). It enables the ethical integration of the following AI functionalities and modules. Predictive analytics modules determine process quality, product quality, and consider the impacts of changes based on data. A generative and automated process planning functionality designs and redesigns robust process plans with various contradicting KPIs by comparing requirements with skills.

Consortium

ASSISTANT is a complex research and development project with 12 partners from 7 European countries. With a multidisciplinary consortium combining key skills in Artificial Intelligence (AI), manufacturing, edge computing, and robotics, ASSISTANT aims to create intelligent digital twins through the joint use of machine learning, optimization, simulation, and domain models. The consortium is composed of the Institute for Machine Tools and Industrial Management (iwb) of the Technical University of Munich, five universities and/or research and technology organizations and six companies.

Acknowledgement

The project "ASSISTANT" is funded with the support of the EU Commission under Grant No. 101000165. We thank the EU Commission for the excellent support. For more information, please visit assistant-project.eu.