Research Topic

| Short Title | Lifetime prediction and monitoring for face gears |

| Start of Project | Q4/2019 |

| Funding | BFS AZ-1379-19 Bavarian Research Foundation, BFS |

| Project Partner | ebm-papst St. Georgen GmbH & Co. KG |

| Contact | Dr.-Ing. M. Otto |

Projekt description

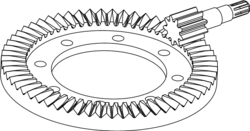

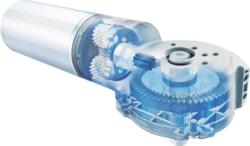

Due to their compact design as well as their high efficiency, face gear drives offer considerable potential for the design of power transmissions. Due to the lack of design standards, the effort required to open up new fields of application for face gear drives is high. Despite this, face gear drives have become established, e.g. for door drives in the railroad sector, due to their advantages in terms of installation space. However, in this and other fields of application, angular gear drives are increasingly adopted to fit the requirements of the application. In the case of bevel or worm gears, local, mechanically complex tooth contact analysis methods are commonly used for this purpose in addition to the standardized, simpler calculation methods. In order to be able to use the advantages of these local methods in an analogous manner for face gear drives, similarly calculation and design methods are required. Despite different approaches described in the literature, an appropriate calculation method is not available.

The development of calculation algorithms, the creation of a calculation program and associated validation tests, including body sound noise measurement, for service life prediction and monitoring are intended to open up new fields of application for face gear drives. As an efficient manufacturing alternative, the hobbing of face gears is being investigated. With this fundamental and comprehensive concept, the research proposal clearly goes beyond pure product development. The decisive content is scientific research.