Bavarian Research Cluster on Customized Digital Engineering for Bavarian SMEs using the example of the powertrain of electric vehicles – Subproject 3: Development of a modular test rig system for electric powertrains

Research Topic

| Short Title | FORCuDE@BEV SP3 Modular Test Rig System |

| Start of Project | Q2/2020 |

| Funding | BFS AZ-1392-19 Bavarian Research Foundation, BFS |

| Website | https://www.bayfor.org/de/unsere-netzwerke/bayerische-forschungsverbuende/forschungsverbuende/association/forcudebev.html |

| Project Partners | |

| Contact | Dr.-Ing. T. Lohner |

Project Description

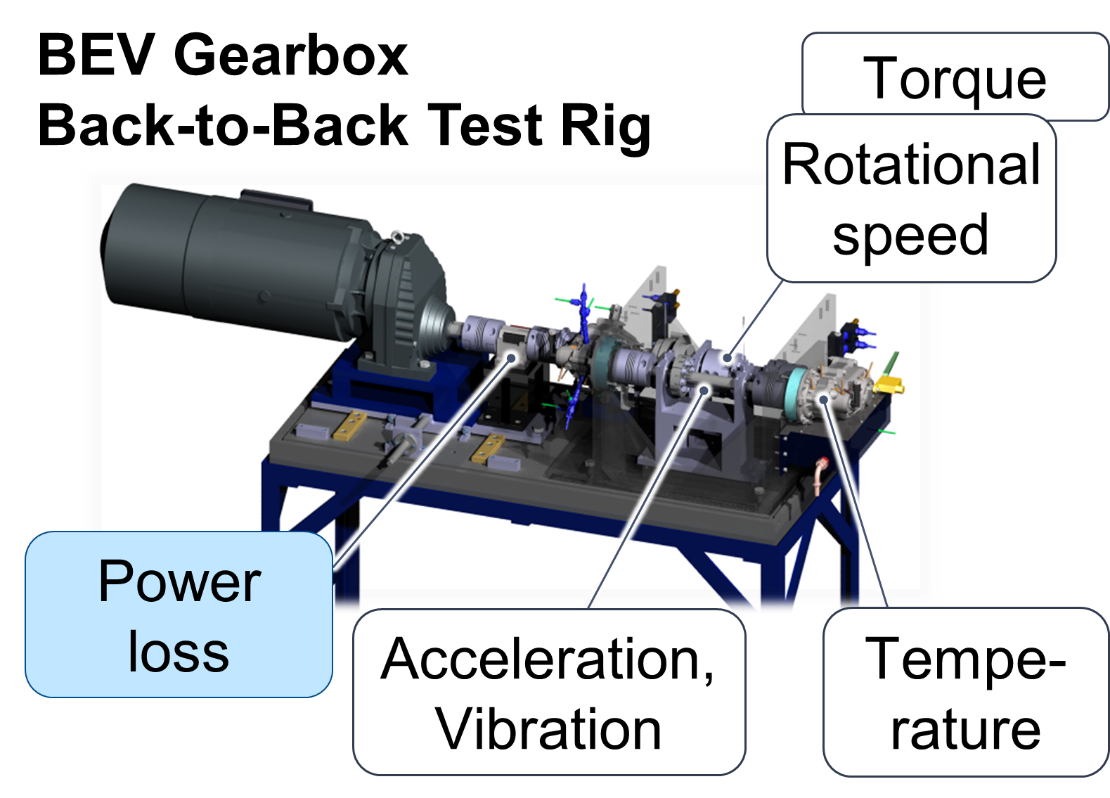

The electrification of automotive powertrain systems is intended to counter the challenges posed by emissions of pollutants and carbon dioxide, which are harmful to health and the environment, as well as noise emissions. Here, battery electric vehicles (BEVs) show great potential. In actual applications, powertrain concepts and topologies of BEVs show very different design approaches, with the focus of current developments being on reducing energy consumption and an accompanying increase in range. However, the high level of dynamics in the development process combined with a large number of variants makes it difficult to predict the future design of electrified powertrains and thus leads to an increased need for flexible testing systems. Within the scope of SP 3 of the FORCuDE@BEV joint project, a test rig system for the experimental analysis of BEV gearboxes is developed on the basis of a modular and generic concept. Established test rig concepts will be modularized with regard to their components (e.g. drive and control system, measurement equipment and sensors, data recording) in order to ensure the subsequent design of variants and the scalability of the test rig and thus its use across variable application and power ranges. The structured design of the modular test rig system as a data model opens up potential for extending digital engineering methods in BEV powertrain development processes to the design of concepts for experimental test rig verification and, following a circular path, to the data generated by the test rig verification. For validation, a test rig demonstrator will finally be derived from the developed modular test rig system, designed and then set up for operation (see figure 1).