Research Topic

| Short Title | Face Gear Service Life Increase |

| Start of Project | Q1/2024 |

| Funding | BFS AZ-1601-23 Bavarian Research Foundation, BFS |

| Project Partner | ebm-papst St. Georgen GmbH & Co. KG |

| Contact | Dr.-Ing. M. Otto |

Projekt description

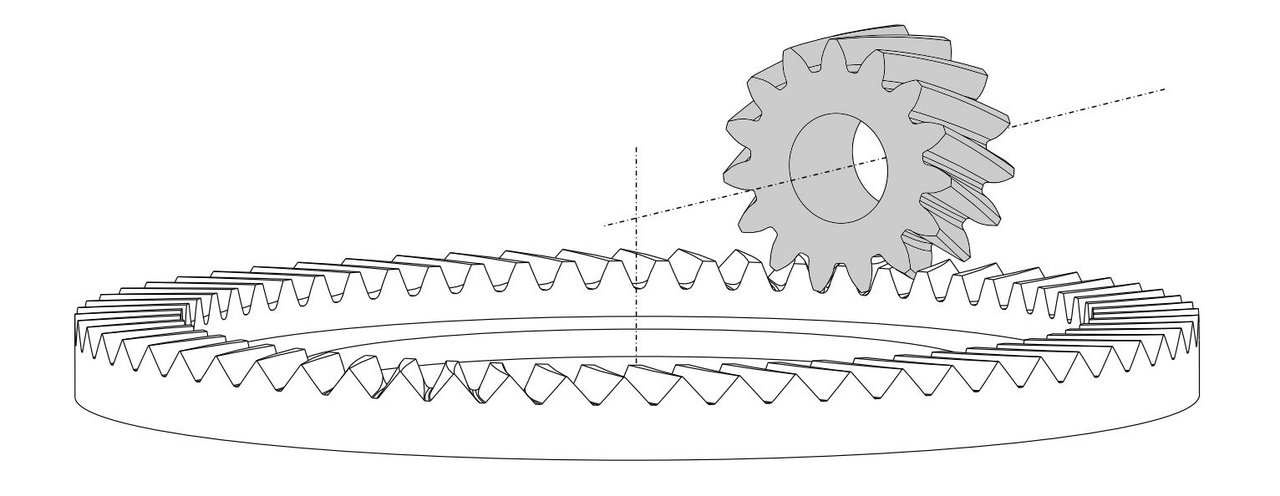

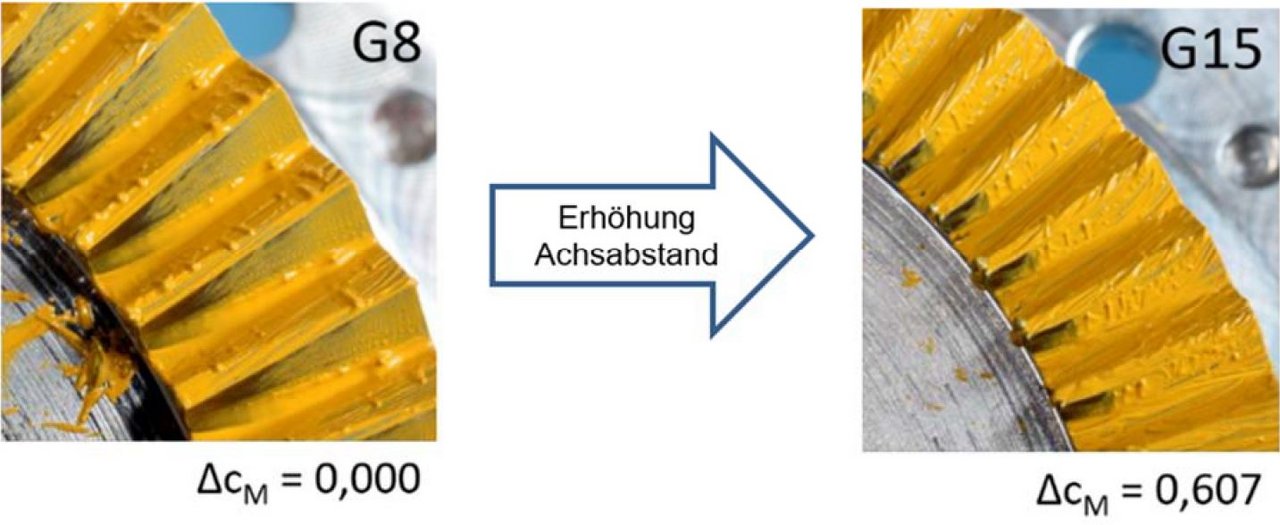

In a face gear drive, an involute cylindrical gear meshes with a face gear wheel at 90° shaft angle. In contrast to the established angular gears (worm and bevel gears), there are no methods for the design and rapid load capacity evaluation of face gear drives, which are indispensable in industrial applications. In addition, there is currently a lack of detailed knowledge about the influence of the gearbox environment on the service life of face gear drives. The elastic gearbox environment results in deviations in tooth contact, which generally have a negative effect on the service life of gearings. Compared to established angular drives, face gear drives have relevant advantages, particularly for small and medium-sized enterprises (SMEs). In this research project, methods for design and environmental analysis are to be developed and experimentally validated. The detailed environmental analysis and design of gearings has the potential to increase the service life and thus maximize the use phase in terms of the circular economy. The increased calculation depth reduces the number of necessary iteration loops in the design, which saves resources for test specimen and test bench tests. In addition, the installation space is optimized, which has a direct positive effect on costs, weight and use of resources and thus ensures appropriate use of materials in accordance with the "12 Principles of Green Engineering" [Ana23].