Research Topic

| Short Title | Light4Speed |

| Start of Project | Q3/2021 |

| Funding | BMWK 03LB3014A Bundesministerium für Wirtschaft und Klimaschutz, BMWK |

| Website | https://light4speed.de/ |

| Project Partners | |

| Contact | Dr.-Ing. T. Tobie |

Project Description

The increasing electrification of the powertrain is significantly reducing the number of transmission components in vehicles. Nevertheless, considerable efforts are currently being made in the area of electric vehicles and their powertrains to identify and implement lightweight construction potential. In addition to the energy storage unit, a decisive weight driver in electric vehicles is currently the electric motor, which must be designed with large dimensions due to the high torques required at low speeds. To circumvent this disadvantage, new concepts based on smaller electric motors are being sought. They provide the required power through maximum speed and correspondingly reduced torque. The very high speeds of the motor must then be harmonized with the output train by a reduction gear. At this point, the reduction gearbox is to be regarded as a decisive enabler technology in order to build vehicles with a high level of acceptance on the market in the future, with reduced weight and a high level of comfort as well as classic driving behavior. In addition, fewer resources, such as copper or rare earths, are also needed with regard to the electric motor.

Analogous to the efforts of recent years to optimize the powertrain of internal combustion engines in terms of weight, the saving of energy in electric vehicles is also of considerable importance. On the one hand, a reduced vehicle weight leads to lower energy consumption and thus to lower CO2 emissions during power generation. On the other hand, the secondary lightweight potential is addressed, which can be scaled up through reduced vehicle mass. An important secondary aspect of energy savings is the utilization of increased ranges with the same energy storage, which has a clearly positive influence on the acceptance of electric vehicles in the market, as a consumer survey on electromobility clearly proves [BON20].

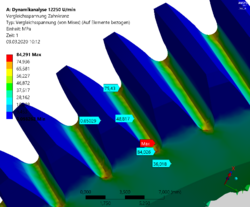

In electric cars currently available on the market, input speeds at the transmission of 12,000 to 18,000 rpm are common (see [OER19, TES20, VWe20, EVD20]). Concept studies and research work are currently mostly concerned with speeds of up to 30,000 rpm, e.g. in [AVL20, SPE17, EFF15]. To further increase efficiency, speed concepts with up to 50,000 rpm are to be used in the future, which are already being developed and investigated in the Speed4E research project [SPE20] at the FZG of the TU Munich. As a result of the maximum speeds, centrifugal forces play an increasing role in gear stress. These are not yet included in the calculation of the tooth root load of a gear according to standardized calculation methods (such as DIN 3990 [DIN87b]/ ISO 6336 [ISO19]), so that this influence can only be mapped using higher-quality, but correspondingly complex calculation methods, such as FEM.

Literature

[DIN87a] DIN 3990-5: Tragfähigkeitsberechnung von Stirnrädern; Dauerfestigkeitswerte und Werkstoffqualitäten (1987)

[ISO19]: ISO 6336 Part 1-6:2019-11: Calculation of load capacity of spur and helical gears (2019).

[SPE20] Speed4E - Hyper-Hochdrehzahl für den elektrifizierten automobilen Antriebs-strang zur Erzielung maximaler Reichweiten. URL: http://www.speed4e.de/. Abrufdatum 07.04.2020.

[BON20] Elektromobilität | Boniversum | Verbraucherumfrage. URL: https://www.boniversum.de/studien/verbraucherumfragen/elektromobilitaet/. Abrufdatum 30.04.2020.

[OER19] DIESEL international: Oerlikon Graziano showed its hybrid and electric technologies at Cti Berlin. URL: https://www.diesel-international.com/alternatives/oerlikon-graziano-hyb-rid-electric/. Abrufdatum 30.04.2020

[TES20] Electric Vehicle News: Tesla Model S drive unit. URL: http://www.electric-vehic-lenews.com/2014/08/teslamodel-s-drive-unit-now-has.html. Abrufdatum 30.04.2020.

[VWe20] Volkswagen Newsroom: e-Motor / 1-Gang-Getriebe. URL: https://www.volkswagen-newsroom.com/de/internationale-fahrvorstellung-des-neuen-e-golf-2858/e-motor-strich-1-gang-getriebe-2864. Abrufdatum 30.04.2020.

[EVD20] ZF Friedrichshafen AG: Elektrischer Achsantrieb. URL: https://www.zf.com/pro-ducts/de/cars/products_29296.html. Abrufdatum 30.04.2020.

[AVL20] AVL List GmbH: AVL Electric drives for future E-Mobility development. URL: https://www.avl.com/documents/10138/12918365/n45518_ss_Transmis-sion_Electric+Drive_E_web.pdf/0f6759c5-26b4-7db1-318a-fc7f823623d8?t=1561380367073&download=true. Abrufdatum 30.04.2020.

[SPE17] FZG & Konsortioalpartner: Speed2E - Innovatives Super-Hochdrehzahl-Mehrgang-Konzept für den elektrifizierten automobile Antriebsstrang für höchste Effizienz und höchsten Komfort. URL: http://www.speed2e.de/download.html. Abrufdatum 30.04.2020.

[EFF15] wbk Institut für Produktionstechnik (KIT): EFFECT 360°. URL: http://www.wbk.kit.edu/wbkintern/Forschung/Projekte/EFFECT360/. Abrufdatum30.04.2020.