Research Topic

| Short Title | SNESYS VII |

| Start of Project | Q1/2024 |

| Funding | FVA-Nr. 320/IX Research Association for Drive Technology e.V., FVA |

| Contact | Dr.-Ing. J. Pellkofer |

Project Description

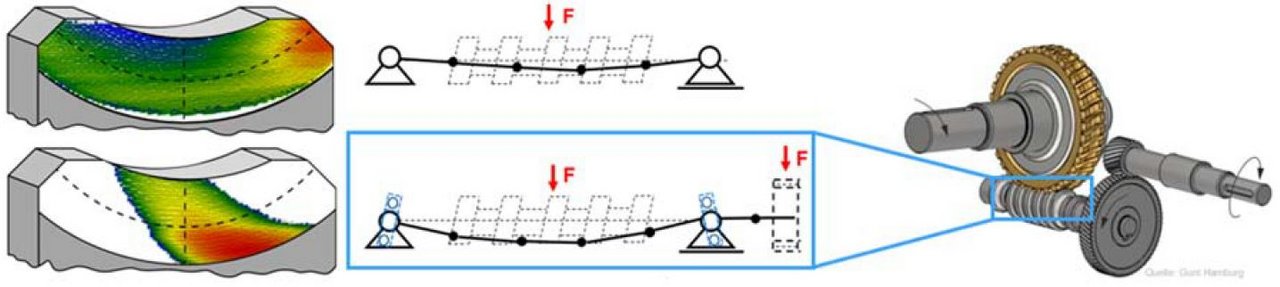

For the calculation of worm gears, the SNESYS program package with the programs SNDIN, SNETRA, SNOPT, ZSB, AWZ and SNEBRE is available to the member companies of the FVA. SNETRA calculates the geometry and the contact pattern as well as local parameters such as pressure and gliding velocity. In the previous research project FVA 320 VIII, a function was implemented by which a deformation of the worm shaft can be specified. The subsequent investigations have shown that an elastic deformation of the worm shaft has a significant influence on the load distribution of the worm gear.

For this reason, further calculation studies on the influence of shaft deformation on the contact pattern are to be carried out as part of the present research project. The focus here is in particular on the effects that further gear stages can have on the contact pattern of the worm gear stage. To perform the calculations, an interface is to be implemented that reads in deformation data directly from RIKOR. RIKOR is a program for analyzing the deformations of entire gear systems. This allows the influence of further gear stages on the operating behavior of the worm gear stage calculated in SNETRA to be taken into account.

A further objective of the project is to evaluate the influence of deviations of the flank topography on the contact pattern and the load distribution. For this purpose, a possibility is to be created in SNETRA to read in externally specified point clouds in order to be able to carry out targeted topography modifications within the scope of the calculation studies. In addition, the function enhancement allows existing worm wheels to be measured in 3D and their actual geometry data to be transferred to SNETRA.

In addition, SNETRA is to output the point clouds of the worm wheels as a 3D CAD model. The .step files generated in this way can then be used for the design and simulation as well as for CAM-based manufacturing.