Research Topic

| Short Title | Design Space Optimization |

| Start of Project | Q2/2024 |

| Funding | FVA-Nr. 421/VI Research Association for Drive Technology e.V., FVA |

| Contact | Dr.-Ing. M. Otto |

Project Description

Gearboxes are used in a wide variety of drive technology applications. The framework and boundary conditions that apply to each of these gearboxes can therefore vary greatly. What they all have in common is the development effort to offer a reliable product for the respective application with resource-efficient use, i.e. economically and sustainably. This goes hand in hand with efforts to achieve drive trains with a high power density, i.e. the best possible utilization of the material used combined with a small size.

The limits of what is technically possible are constantly being pushed back, not least by the continuous development of manufacturing possibilities and process reliability as well as the possibilities for analyzing and simulating technical systems.

This also applies to the development of high-ratio planetary gearboxes. Recommendations on feasible transmission ratio ranges for various designs are known from the literature and recognized in research and industry. However, it is clear that these ranges determined under certain boundary conditions do not represent fixed limits. It is known from industrial applications that the specified transmission ratio recommendations can be exceeded to a considerable extent.

This means that the designer has no precise knowledge of the limits of the designs based on gear geometry and load capacity, which means that potential remains unused in development.

The available installation space is often a decisive criterion in gearbox design, particularly in drive trains with high power density. However, there are no known integrated procedures or application programs that support the designer by optimizing gear dimensioning to the available installation space.

Knowledge on the dimensioning, design and analysis of gears is available and described in algorithms. The consideration of restrictions is also possible in dimensioning with the FVA program "GAP" (gear design program), but not implemented in the context of an available installation space volume.

Research Objective

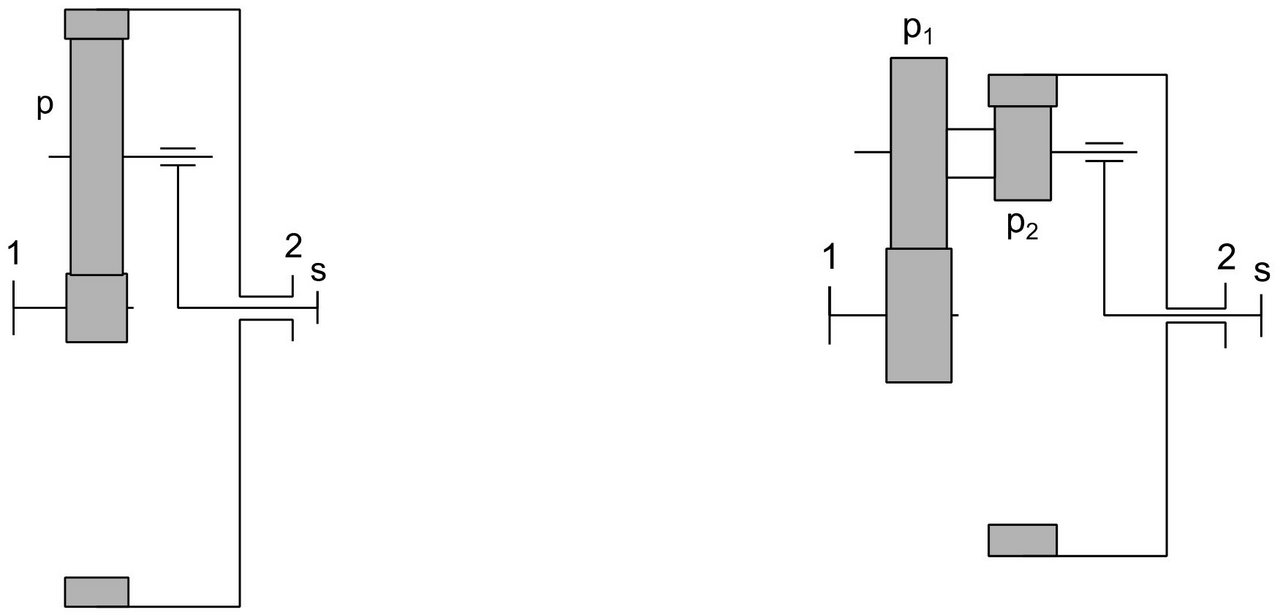

The aim of this research project is to extend the state of research with regard to the technically feasible transmission ratio ranges of selected planetary gearbox designs (minus gearboxes). An essential part of the project is the scientific analysis of the topologies shown in Figure 1.

The findings are the starting point for deriving a design strategy for later implementation in the gearbox design program.

The project also aims to develop a mathematical installation space model with the associated collision analysis between the individual gearbox main elements. This will enable gear dimensions to be optimized in terms of installation space. As a result, an application-optimized gear design can be built upon at an early stage of development.