Further Investigations on the Consideration of Microgeometry within the Load Carrying Capacity Calculation Methods of the Standard Method B

Research Topic

| Short Title | KNplus |

| Start of Project | Q3/2022 |

| Funding | FVA-Nr. 49/XV Research Association for Drive Technology e.V., FVA |

| Contact | Dr.-Ing. J. Pellkofer |

Project Description

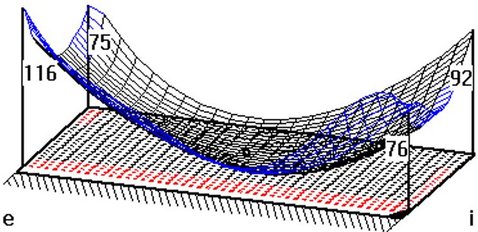

The actual ISO 10300:2014 for the calculation of the load carrying capacity of bevel and hypoid gears is based on a virtual cylindrical gear also specified in ISO 10300 (Edition 2014). The virtual cylindrical gear represents the macro-geometry of a bevel or hypoid gear in a simplified but sufficiently accurate way. The influence of the micro geometry is considered by a load distribution exponent e. This exponent e considers two discrete states of low- and high-profile crowning. At the moment, there is no definition of the terms low and high profile crowning available. In a previous completed research project, the more detailed definition of the exponent e was carried out to be not expedient. Therefore, as part of the research project, other approaches should be identified to obtain a more accurate consideration of the micro geometry and modify the calculation method B in ISO 10300 (Edition 2014) accordingly.

Additionally, the behavior of the calculation method ISO 10300-2:2014 regarding an in-creasing mean spiral angle will be investigated. Current findings in the application of the ISO 10300-2:2014 shows, that, contrary to experience and other calculation methods, the safety factors against pitting decreases with increasing mean spiral angle.

The application of calculation methods of different standardization organizations for de-termination of the load carrying capacity of bevel gears shows partly significant differences in the calculation results. A calculation study will be carried out using different standard calculation methods to identify differences and to clarify their influences on the calculation result. Accompanying the new released standard calculation methods ISO/TS 10300 20 and ANSI/AGMA 2003 D19 should be implemented in the bevel gear standard calculation program KNplus.

In order to improve the usability and software quality of KNplus, further program optimizations should be carried out as part of the re-search project.