Research Topic

| Short Title | Scuffing load capacity of worm gears |

| Start of Project | Q3/2022 |

| Funding | FVA-Nr. 799/II, IGF-Nr. 22480 N/1 Federal Ministry for Economic Affairs and Climate Action, BMWK |

| Contact | Dr.-Ing. J. Pellkofer |

Project Description

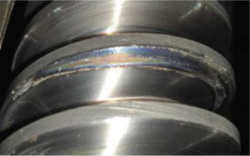

The use of higher-strength materials, such as gray cast iron or steel, for worm gears, which up to now have mostly been made of bronze, offers advantages in terms of the power density and economy of worm gear drives. However, when such materials are used, scuffing often dominates as a load capacity-limiting type of failure. In order to be able to design worm gear drives reliably against scuffing, a methodology for determining scuffing resistance was developed in the previous research project FVA 799 I. However, this methodology requires further development and validation.

In the present research project, therefore, the two main components of the methodology are to be extended. These are a calculation of the surface temperature and a test procedure for determining material-lubricant load-carrying capacity characteristics. The calculation is to be extended by means of simulations so that the roughness and the distribution of the bulk temperatures can be taken into account in more detail. The test procedure is to be optimized to obtain reproducible results. For this purpose, experimental investigations on the influence of roughness and running-in on the scuffing load capacity are planned. In order to finally verify the functionality of the methodology, it will be applied to various materials, lubricants and gear tooth designs.

The intended results should provide a reliable methodology for determining scuffing resistance that can be used in the development of worm gear drives following the project. As a result, the portfolio of worm gear drives with worm wheels made of higher-strength materials can be expanded, and power density and cost-effectiveness can be increased.