Development of a Test Method for Determining the Tooth Root Load-Carrying Capacity of Polymer Gears According to VDI 2736 Using a Pulsator

Research Topic

| Short Title | Kunststoff-Puls |

| Start of Project | Q2/2021 |

| Funding | FVA-Nr. 932/I, IGF-Nr. 21797 N Federal Ministry for Economic Affairs and Climate Action, BMWK |

| Contact | Dr.-Ing. T. Tobie |

Project Description

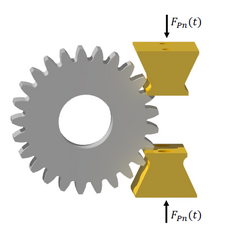

The strength values of gears are usually determined on the basis of experimental lifetime tests. A difference must be made between the tooth root load-carrying capacity and the tooth flank load-carrying capacity. Investigations on the tooth root load-carrying capacity are mainly carried out on pulsator test rigs, whereas experimental tests on the tooth flank load capacity are performed on back-to-back test rigs. However, the pulsator test is the more economical test method overall. For steel materials in particular, the pulsator test has become the standard method for determining tooth root load-carrying capacity, which is essential for the application-specific design of gears. To consider the differences between the stresses in the pulsator and the back-to-back test, validated coefficients are available for steel gears that allow reliable conversion of the strength values between the two test methods. However, the application of these factors to polymer gears can lead to significant deviations. Difficulties are caused above all by the different material behavior of polymer compared to steel. A major challenge is the relatively high tooth deformation under load caused by the significantly lower stiffness of polymer materials. This results in a significant change in the bending lever arm of the force application point under load, which can lead to a reduction in the occurring tooth root stress. Because of the difficulties mentioned, tests on the tooth root load-carrying capacity of polymer gears have therefore so far been carried out mainly in back-to-back tests. The suitability of the pulsator test for investigating the tooth root load-carrying capacity, on the other hand, has not yet been fully clarified for polymer gears. To make the advantages of the pulsator test usable for polymer gears as well, a standardized test method adapted to the specific material properties of polymers is required. The aim is to create a way of determining material properties and investigating the tooth root load-carrying capacity of thermoplastics quickly, efficiently, and cost-effectively.