Test Methodology for Assessing the Performance of Lubricants for Gears in E-Mobility Applications: Reliable Assessment of the (Scuffing) Load Capacity of E-Mobility-Lubricants

Research Topic

| Short Title | Test Methodology E-Mobility-Lubricants (E-Fluids@HighSpeeds) |

| Start of Project | Q1/2023 |

| Funding | FVA-Nr. 988/I, DGMK-Nr. 833 Research Association for Drive Technology e.V., FVA German Society for Sustainable Energy Carriers, Mobility and Carbon Cylces e.V., DGMK |

| Contact | Dr.-Ing. T. Tobie |

Project Description

The use of electric motors instead of internal combustion engines in the powertrain of vehicles offers great potential for environmentally friendly mobility. In addition, by operating at high speeds and saving mass at the same time, the efficiency and power density of electric drives can be increased. For this reason, current developments in the automotive industry show a strong trend towards the use of electrified powertrains.

Different drive concepts in purely electrically powered vehicles continue to necessitate the use of transmissions in the powertrain. The tribological load carrying capacity of the gear teeth in the transmission is ensured by using a suitable transmission lubricant. Lubricants often contain performance additives whose effect is strongly dependent on the operating conditions, especially the lubricant temperature. Due to the complex physicochemical interactions between the lubricant components and the gear material, the performance of gear lubricants cannot yet be sufficiently estimated theoretically and must be verified and proven in lubricant tests.

In standard test methods, state-of-the-art lubricants are examined at speeds from n = 2,250 min-1 to a maximum of n = 4,500 min-1, while speeds of up to 20,000 min-1 are currently encountered in e-mobility. In future developments, even significantly higher speeds are to be expected. Due to the greatly increased speed compared to standard test methods, lubricants used in e-mobility will therefore be used under significantly different operating conditions than can currently be tested.

First investigations are already showing influences with regard to micropitting and pitting load capacity and, in particular, scuffing load capacity at higher speeds. These initial results underline the relevance of further investigations into the load carrying behavior of the lubricants under e-mobility conditions compared with the previous standard oil test methods.

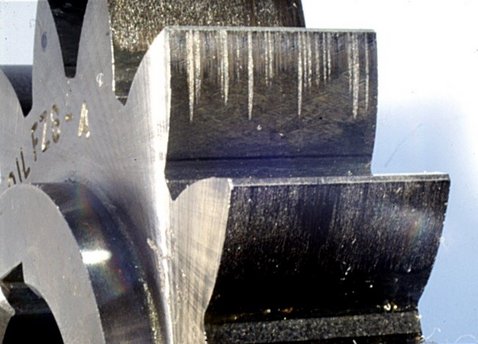

The research project will therefore examine whether the current test procedures for assessing the load carrying capacity of lubricants with regard to the relevant tooth flank damage mechanisms are meaningful for the operating conditions in e-mobility applications. The focus of this project is on the systematic investigation of the scuffing load capacity in the FZG high-speed test rig (modified FZG back-to-back gear test rig); selected random tests on pitting, micropitting and wear behavior are planned. A practical application and release test with regard to seizure is to be developed, in which conditions close to the application and typical circumferential speeds of e-mobility applications are mapped.