WeldingWatch – Development of an adaptable inline process monitoring and control system for laser-based battery contacting using machine learning algorithms to reduce the scrap rate

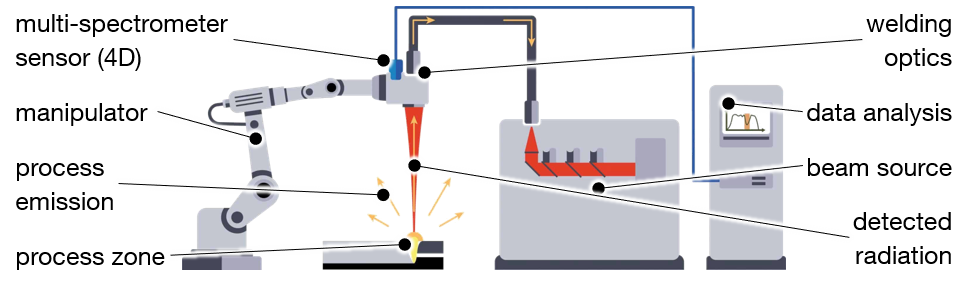

With the increasing market share of electromobility, the importance of laser beam welding as a manufacturing process for the electrical contacting of battery cells is growing. The optical multispectral analysis provides the opportunity for process monitoring in this challenging joining task.

The controlled heat input into the component enables the laser beam welding of temperature-sensitive components, such as lithium-ion batteries. Through pulsed radiation in the nanosecond range, seam widths in the sub-millimeter range with sufficient penetration depth can be achieved even with challenging material combinations.

Objective of the project:

A process control for this innovative joining process is being developed in the collaborative project WeldingWatch. For this purpose, the process light is captured and analyzed using an optical multi-channel spectrometer provided by the project partner, the 4D Photonics GmbH.

Process investigations:

Due to the criticality of the zero clearance between the two joining parts, a dedicated clamping system is initially developed to investigate the influence of the clamping force. This system is then used to identify correlations between the weld quality and the spectrometer sensor data. Based on this data, a control system for the welding process is also developed, aiming to significantly reduce the scrap rate.

Evaluation methodology:

The correlations determined between process emissions and weld seam quality are modeled data-based using machine learning methods. An important factor in this project is the model´s flexibility, allowing an easy transfer to other materials with minimum personnel effort. In order to enable a broad applicability, the control system and the data-driven quality

Acknowledgements:

“WeldingWatch” is a collaborative project, which is supported by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) with funding code KK5033604KL1 and supervised by the AiF Projekt GmbH (AiF). We would like to thank the BMWK and the AiF for their support and for their effective and trusting cooperation as well as our project partner the 4D Photonics GmbH.