Intelligent connection and convertibility of production and intralogistics in a dynamic environment using convertibility of Automated Guided Vehicles

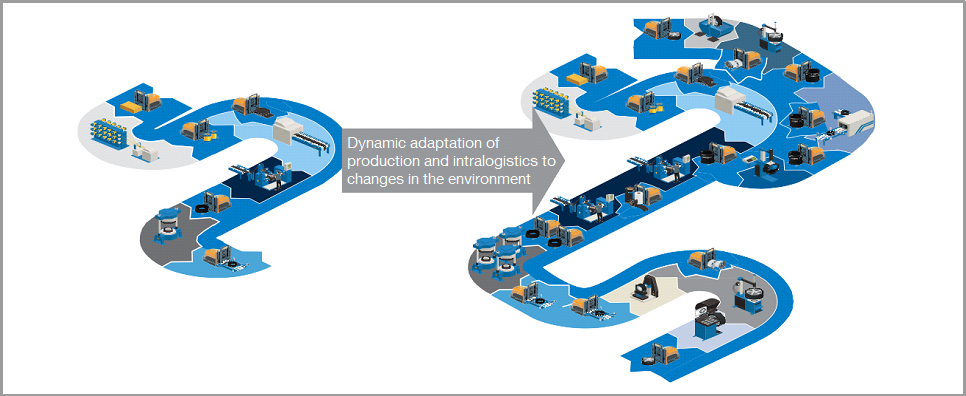

Based on megatrends such as digitization and individualization, customer and product requirements are constantly changing. Companies and their production must be able to adapt quickly and efficiently to changing products at all times. Due to Industry 4.0, production and intralogistics are increasingly connected and developing into a digital unit. Against this background, the entire supply and value chain is in a state of constant change. In the field of intralogistics, Automated Guided Vehicles (AGVs) with their characteristics such as a high degree of flexibility and reliability represent a promising starting point for these challenges. An intelligent connection of production and intralogistics is desirable through the use of convertible AGVs, which have the ability to adjust quickly and efficiently to the situation-specific conditions in a dynamic environment.

The agile adjustability of production to changing requirements is a decisive competitive advantage and is continuously optimized in industry and science. It is characterized by a high degree of connection and changeability. In this context and in addition to production, the intralogistics which supply and connect it must be able to adjust flexibly. An increasing tendency towards new publications indicates that industry and science are also increasingly taking interest in this area.

The two divisions of production and intralogistics have generally been optimized independently of each other up to now. Their increasingly close connection, however, requires an interdisciplinary, holistic approach. Previously, there is no standardized procedure for intelligently connecting and transforming production and intralogistics in a dynamic environment using convertible AGVs.

The aim of the dissertation project "IVWPIdU - Wandelbares FTS" is the development of a process model for the intelligent connection and changeability of production and intralogistics in a dynamic environment by using convertible AGVs. A digital tool for the redesign and optimisation of production and intralogistics processes will be made available to factory, production and logistics planners.

The process model should cover all relevant elements of connected production and intralogistics. Above all, the economic, technical and qualitative aspects are relevant. In this context, particular importance is attached to the integration of a continuous improvement process with short cycle times and iterations. In addition to a high degree of compatibility and integrability, the process model must be easy to adjust and scale in line with the situation as a prerequisite for widespread use. In this respect, it is also important that it can be used intuitively and is based as far as possible on common principles, methods, techniques and tools from practice. Furthermore, the process model should be capable of being modified and extended for continuous improvement.

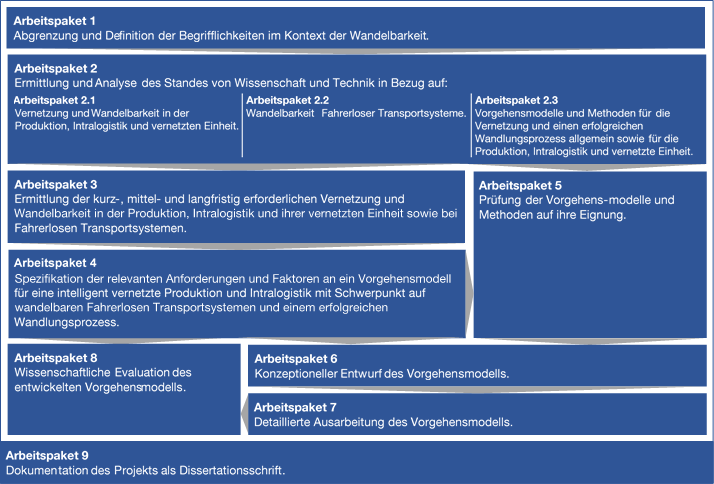

The procedure of the dissertation project is based on a modified variant of the V-Modell XT and is divided into the following eight work packages:

At the beginning, based on a literature search, the individual terms in the context of changeability for the project and the dissertation are to be distinguished and defined from each other (AP1). In the second work package, the state of the art of science and technology will be worked out and analysed in three steps by means of a literature and market research. The first part deals with connection and changeability in production and intralogistics as well as in the interconnected unit. The changeability of AGVs is discussed in the second part. Finally, in the last part, an examination of existing process models and methods for connection and a successful transformation process (AP2) is carried out both in general and for production, intralogistics and the connected unit. Based on this, a study will be conducted by interviewing experts from industry and academia to determine the type and degree of connectivity and changeability required in production, intralogistics and their connected unit as well as in AGVs in the short, medium and long term (AP3). The evaluated study results serve as a basis for the specification of the requirements and factors relevant to a process model for intelligently connected production and intralogistics with a focus on convertible AGVs and a successful transformation process. This step is accompanied by Requirements Engineering (AP4). The resulting process models and methods from the second work package are to be tested for their suitability under consideration of the previously defined requirements and factors (AP5). In the next step, a conceptual design of the process model is carried out, taking into account the previously defined requirements and factors as well as the resulting results from the fifth work package on process models and methods (AP6). Part of the seventh work package is the detailed elaboration of the conceptual process model (AP7). In the eighth work package, a scientific evaluation of the procedure model developed is carried out on representative case studies, including the requirements defined in the fourth work package (AP8). The dissertation project is to be documented over the entire period in form of a dissertation publication, which is the last work package (AP9).