Along the competences, the team of the chair works in the research groups presented here. In these groups, we pursue different research topics and projects in the fields of material flow technology and logistics and drive them forward with new innovative ideas and approaches. This research groups contribute significantly to scientific progress in the respective subject area.

Initial situation

Robotics hardware and software are currently developing rapidly and enabling new fields of application. Particularly in logistics, these developments are highly relevant, as processes here are very complex and up to now often manually operated. Therefore many use cases, such as the transport of materials or the gripping of products, are to be explored.

Our Goals

Our vision is a sustainable, human-centred optimisation of the internal material flow through the use of robotics. To get closer to this goal, we conduct technology assessments and improve the environment perception of mobile robots through sensor technology as well as image recognition. We also develop innovative, holistic control solutions for heterogeneous robot fleets and investigate the increasing collaboration between humans and machines under the heading "Future of Work“.

Current projects

Development projects

- Autonomous Tugger Train

- Autonomous Grasping

- Connected Intralogistics

Research projects

Contact Person

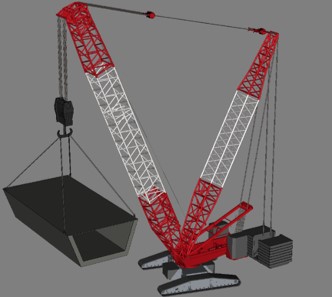

Problem & scope of tasks

In the development and design of supporting structures and materials handling systems, the precise determination of mechanical stresses is of crucial importance. On the one hand, this concerns the static stresses, on the other hand, the vibration behaviour of the structures during working movements and under moving or variable loads. For reasons of time, money and safety, experimental determination of the stresses is not possible in many cases. Therefore, the research group "Dynamic Simulation" investigates and develops calculation methods based on finite element, multi-body and discrete element methods. The focus is on the problem-oriented use of existing methods as well as the development of new calculation methods.

Objectives

The central objective of the research group is to develop effective and accurate calculation methods for determining the mechanical stresses of supporting structures and materials handling systems. This should increase the safety of the design and facilitate the application of the standards. Last but not least, the precise knowledge of the dynamic stresses supports the lightweight construction of structures and thus enables more energy-efficient drive solutions.

Research projects

- Dynamic Analysis and Control of Flexible Long Boom Manipulator

- NODYA – Finite Elemente Programmsystem

- MARS – Methodology for the practical design of the rail-wheel system for stacker cranes

Contact Person

Initial situation

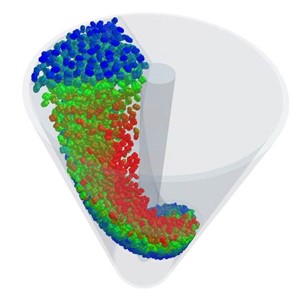

With the help of simulation models, material calibration, increasing computational power and the use of the Discrete Element Method (DEM) prototype costs can be reduced and system availability can be increased.

Goals

Our goal is to establish DEM in practice through the development of simulation and material models. In addition to the future in-house material calibrations, complex simulations with cohesive materials are also to be carried out through increased computing power. Application-oriented research on continuous conveying technology and the associated optimization of existing systems will continue to be associated with the name fml.

Current projects

Contact Person

Inital Situation

There are currently two problems in the design of work in the logistics. On the one hand, there are often unattractive jobs in logistics due to the constantly rise of costs. On the other hand, if new technologies are introduced in the company, the complexity of the work increases and the required competences of the employees change.

Vision

The central goal of the research group is to reduce the negative effects of work on people. Ergonomic job design can increase not only productivity, but also employee motivation and satisfaction. To achieve this goal, for example, one research topic is the rise of intuitiveness of the operation of work machines. This can reduce errors on the one hand and increase safety on the other.

Current Projects

Contact Person

Initial situation

Angesichts des Klimawandels und globaler Ressourcenverknappung kann und muss die Logistik ein wesentlicher Enabler nachhaltigen und ressourceneffizienten Wirtschaftens sein. Hierzu bedarf es der Verfolgung ganzheitlicher Ansätze und der Entwicklung intelligenter Prozesse und Technologielösungen.

Key areas

Die Schwerpunkte der Forschungsgruppe umfassen dabei die Circular Economy (zirkuläre/reverse Logistik, nachhaltige Lieferketten), ressourceneffiziente Intralogistik (Energieeffizienz von Logistikanlagen, Einsatz alternativer Antriebe und regenerativer Materialien) sowie nachhaltige Transportlogistik (Urbane Logistik und Mobilitätskonzepte, emissionsarme Baulogistik, Packaging).

Current projects

- CirculaTUM – Research Alliance for Circular Economy

- FFZ70 – Deployment of 70 hydrogen-powered conveyors at the BMW plant Leipzig

- OptiFit – Determination of the optimal retrofit timing for intralogistics assets

Contact Person

Mauß, Niclas-Alexander; M.Sc.

Initial situation

Sustainability, holistic interconnectedness and a shortage of skilled workers place complex demands on future work systems and machines.

Goals

Development of innovative solutions that meet the challenges of work systems. Cutting-edge research especially in the areas of "Data Analysis & Modeling", "Robotics, Autonomy & Assistance", "Processes & Work Systems" and "Safety".

Current projects

- Data Analysis & Modeling – Process Data Analysis

- Robotics, Autonomy & Assistance – Traversability Maps, Teleoperation

- Processes & Work Systems – Data Trust Model

- Safety – Sensor Stacks

Contact Person

Initial situation

Currently, heterogeneous conveyor technology in intralogistics is being further developed to meet the demand for ever higher performance. In particular, the versatile optimization potentials of existing technology and application fields of new technologies are being researched.

Our Goals

Our goal is the optimization of classical conveyors/conveyor technology and their planning in intralogistics, such as stacker cranes, forklifts or shuttles, in order to achieve higher productivity, better space utilization, reduced investment and operating costs, and lower energy consumption. Thereby we use the networking of specific knowledge at the Chair fml.

Current projects

Development projects

- dynamische hybride Lagersysteme

- innovative Planungstools

Research projects

Contact Person

Initial situation

In addition to the increasing customer demand for individualized products, a large number of dynamic factors affect production and its supplying logistics as a service provider in the environment. As a result, complex requirements are emerging such as the ability to change, performance, dynamism, ...

Goals

The central goal of this research group is the optimization of the supply chain from the supplier via the internal production supply to the customer through intelligently controlled and transparent processes. This goal is to be developed through application-oriented research in the areas of process optimization, cooperation between different transport systems, and changeability.