AGenDa

Automated generation of digital data from existing intralogistics systems for an efficient model generation

Models or digital twins can be used in different phases along the life cycle of intralogistics systems. For example, the engineering process can be supported with simulation and emulation by testing strategies and control codes before the plant exists. The use of models is also very useful for retrofits of existing plants. Particularly in the case of time-critical projects, virtual commissioning, for example, ensures a completion on schedule.

However, depending on the simulation purpose and the data basis required, the effort for creating models can be very high. Procedures for (semi)automatic model creation can help here. A prerequisite for this is current digital data of the plant, which is required for a (semi)automatic model generation. Especially with existing plants, however, these data are rarely complete, up-to-date and digital.

This leads to the fact that models for the purpose of retrofits can only be created with a high manual effort.

The objective of the research project is to reduce the effort involved in creating models for existing intralogistics systems and thus enable an economic use of models in retrofit projects.

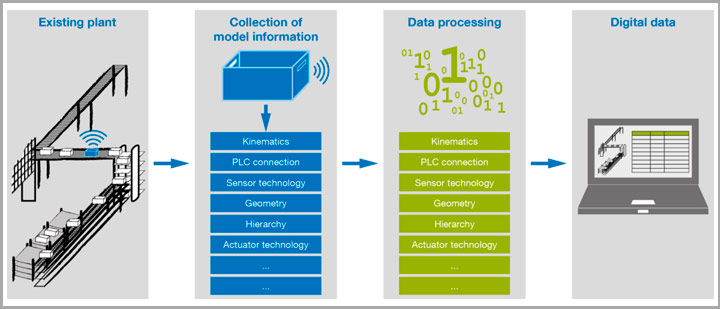

A method for the automated extraction of physical data from existing plants will be developed. The data collected in this way will then be converted into a generally valid digital form so that it can be reused for a (semi)automatic model generation.

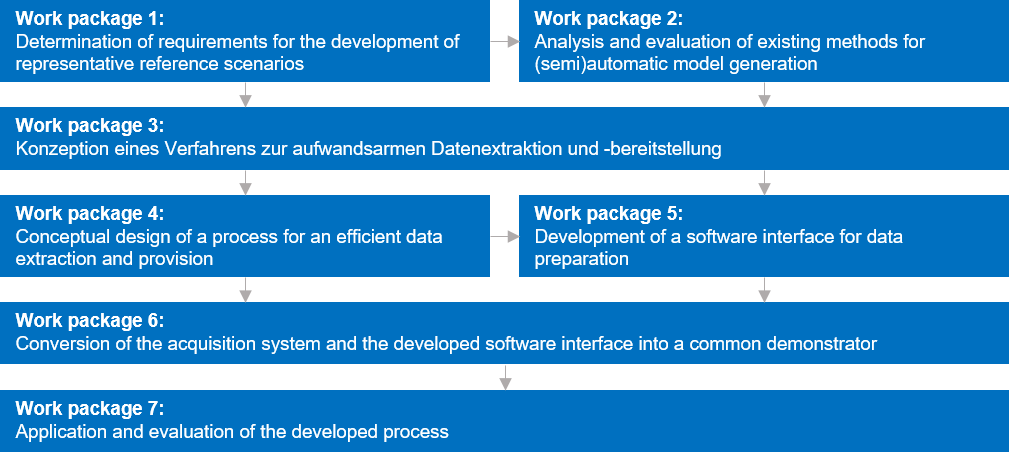

In order to create a basis for the project, at the beginning reference scenarios will be developed which are intended to map a range of layout and control configurations. Furthermore, different simulation purposes and the data relevant for the respective purpose are determined (WP 1). Subsequently, various already existing methods for (semi)automatic model creation will be compiled in a comprehensive research and the required data format will be discussed (WP 2). In order to close the gap between existing reference scenarios and (semi)automatic model generation, a methodological procedure for an efficient data extraction will be designed in the next step (WP 3). As a result, the next step will include the development of an acquisition system, e.g. an intelligent box, which is capable of extracting physical data from a plant and making them digitally available (WP 4). The development of a software interface for processing the digitally determined data into a format suitable for (semi)automatic model generation represents the final conceptual step (WP 5). From these results, a demonstrator is created (WP 6), which is then used to apply and validate the developed method (WP 7).

- Gebhardt Systems GmbH

- HAWE Hydraulik SE

- Jungheinrich Logistiksysteme GmbH

- LEWAGA GmbH & Co. KG

- Siemens Deutschland, PID

- Siemens Postal, Parcel & Airport Logistics GmbH

- SimPlan AG

- tarakos GmbH

- viastore SOFTWARE GmbH

- WLC Weissenborn Logistik Consulting

The IGF project 20680 N/1 of the Forschungsgemeinschaft Intralogistik / Fördertechnik und Logistiksysteme (IFL) e.V., Lyoner Straße 18, 60528 Frankfurt am Main, was funded by the AiF within the programme for the promotion of joint industrial research (IGF) of the Federal Ministry of Economic Affairs and Climate Action on the basis of a resolution of the German Bundestag.