Building Information Modeling stands for the consistent use of a digital building model over the entire life cycle of a building - from the design, planning and execution to the operation of the building. The concept goes hand in hand with the idea of significantly improved data exchange and the resulting increase in planning efficiency and quality by eliminating the need for time-consuming and error-prone re-entry of information. The BIM methodology has been intensively researched for many years and is currently beginning to establish itself in practice.

In this context, a number of more recent national initiatives should be mentioned, such as the convening of standards committees at VDI and DIN, the BIM pilot projects of the federal government and the establishment of planen-bauen 4.0 GmbH as a national BIM platform. In the course of these developments, it is to be expected that the BIM methodology will soon establish itself as a standard in Germany as well.

The construction industry is thus facing an enormous technological change - away from analogue work with 2D drawings towards modern digital work with intelligent 3D models.

Especially at the interface between construction planning and execution there are still many open questions that need to be thoroughly investigated and researched before the practical benefits of the BIM methodology can be fully exploited.

Currently, construction planning is mainly carried out manually. Aspects such as ensuring productivity and ensuring safety-critical aspects have not yet been formally examined and can only be taken into account through the experience of the responsible engineers. In view of the possibilities provided by Building Information Modeling, this is no longer up to date.

The planning of the construction process has a strong impact on the productivity of the construction project and thus a large influence on the later adherence to the given time and cost framework. Due to the complex interaction of many involved companies and the overlapping of different construction phases, the precise planning of the construction process is extremely time-consuming and error-prone for the responsible personnel.

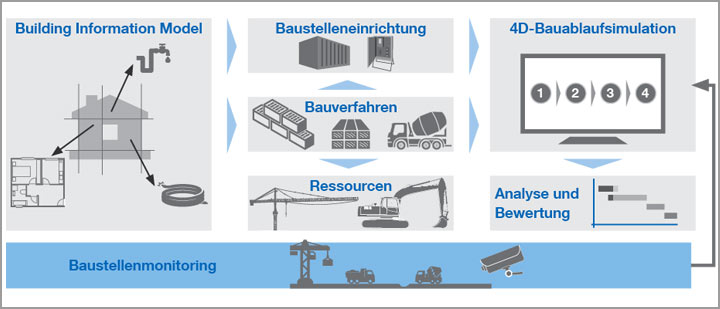

The aim of the project is to develop largely automated methods of construction sequence simulation in order to support the planning of construction sequences in the best possible way and to enable a detailed variant investigation of construction site layouts. Building Information Models are to serve as a basis for the creation of possible variants for the construction site layout planning, which will then be analysed and evaluated with regard to safety and productivity in the construction process simulation. The preparation of existing models in order to be able to use them for the construction site equipment and simulations is an important cornerstone of the project.

In this context, methods have to be developed to formally specify the requirements for building models. In doing so, it must be recorded in as general a form as possible which additional information must be contained in the Building Information Models (BIM) in order to supply the construction sequence simulation with the required input information. For this purpose, methods are to be developed to extract large parts of the required information from the BIM model. The existing information on component types and materials must be supplemented by further information, e.g. on the construction method to be used and the required resources.

With the chosen research approach, concepts and prototypical implementations of software tools are to be developed which will enable the responsible actors in construction planning and execution to create, analyse and evaluate different variants of construction site equipment. Therefore, the development of a three-dimensional, semi-automatic variant generation of the construction site layout on the basis of production and safety-relevant criteria is a central component of the research project. Initially, several possible construction site equipment variants are to be identified using a rough approach through the development of intelligent planning algorithms. In the next step, the individual variants are examined in the construction sequence simulation for the target variables safety and productivity in order to exclude individual variants generated in advance and make the best possible final selection.

Since the construction process is very volatile due to endogenous and exogenous influences, the information available in the work preparation, e.g. at process times, must be validated during the construction process. Therefore, monitoring procedures should be used in order to be able to react dynamically to changes in the construction process and/or resource allocation.

- Bauer Spezialtiefbau GmbH

- Deutsche Doka Schalungstechnik GmbH

- Hilti AG

- Knauf Gips KG

- Max Bögl Bauservice GmbH & Co. KG

- Nemetschek Allplan Systems GmbH

- Obermeyer Planen + Beraten GmbH

- Peri GmbH

- PPI Informatik - Dr. Prautsch & Partner

- Siemens Industry Software GmbH & Co. KG

- SSF Ingenieure GmbH

- think project! GmbH

- TUM - Lehrstuhl für Computergestützte Modellierung und Simulation