The aim of the joint project iSLT.NET is the conception, prototypical realization and evaluation of a network for smart and modular special load carriers. Thus, the technical feasibility, the potentials and the economic efficiency of networking modular special load carriers are to be demonstrated.

So-called special load carriers are used for large, bulky or sensitive components and assemblies, such as engines or gearboxes. These containers are specially manufactured load carriers for a component, which have a very low degree of standardization. They are usually developed and designed parallel to the product development process and manufactured in comparably small quantities. For cost reasons, special load carriers are usually made of simple welded steel components. This construction method makes a conversion and reuse of the special load carrier for new components and assemblies difficult or even impossible. In particular, the ever-shorter product life cycles mean that the special load carrier only has a short service life. This leads to high investment costs for special load carriers, because they need to be newly manufactured for every new product series. New concepts for modular special load carriers have already been investigated in recent years, which allow the disassembly at the end of use and a reuse of container parts. However, both the previously developed approaches of a modularized special load carrier and the associated container management systems are not suitable for cross-company and cross-industry use.

Normally special load carriers are equipped with a paper consignment note and a barcode for optical identification within the material flow. Though most companies currently lack a continuous connected IT and communication infrastructure to achieve a 100% transparent container flow. This lack of transparency means that no track & trace, reporting, monitoring or decentralized retrieval of process information is possible to support decision-making. This can easily lead to container shrinkage, for example. This lack of transparency also eliminates optimization potential for the processes associated with container supply chain. Even an optimization of the cross-company supply chain cannot be carried out at all or only with difficulty due to the usually separate IT systems.

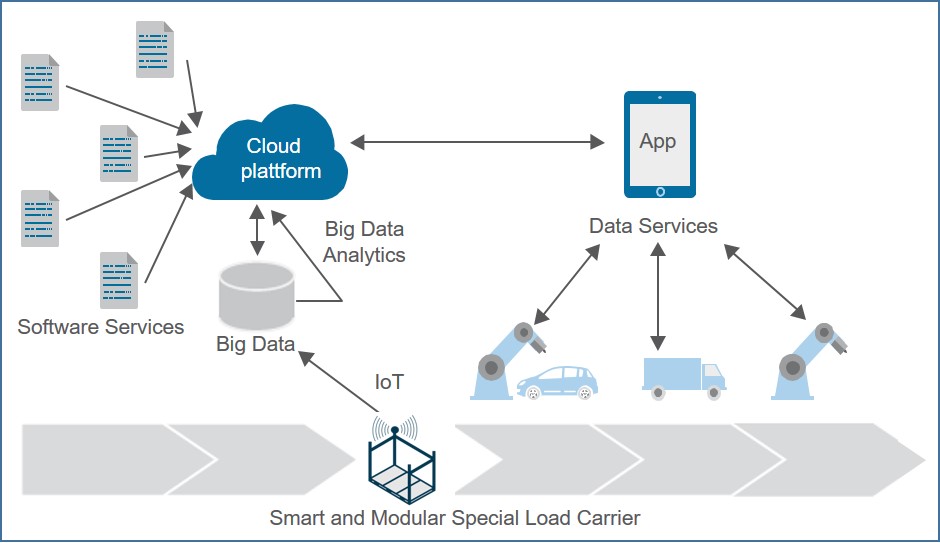

The objective of the joint project iSLT.NET is therefore to address these problems, to design a network of smart and modular special load carriers and to implement this network in a supply chain using a novel business model. As one of the first steps a standardized modular system for special load carriers is to be developed, which makes an industry-wide reconfiguration and reuse of the modules possible. Part of this modular system is the integrated IoT technology (Internet of Things), which will enable the decentralized collection and retrieval of data. The identification of process-relevant data in the context of load carrier management (e.g. location, loading condition, temperature, vibration, defects) will be analysed as well. A cloud platform with corresponding software services will be created to enable cross-company use of this data. Based on the collected data, these services will provide new functions for the participants and thus generate benefit for the entire supply chain.

The distribution of rights and roles for actors involved in the supply chain is to be determined in combination with a new business model, for example "container-as-a-service". The business model should meet the requirements and possibilities of smart and modular special load carriers in the context of industry 4.0. After an initial test of this iSLT network in a demonstrator supply chain between the participating research facilities, a porotype will be implemented between the industrial partners. This practical test is intended to demonstrate the technical feasibility, the potential and the economic efficiency of networking smart and modular special load carries. Based on the knowledge gained, recommendations for action for an industry-independent use of the iSLT.NET network will be derived.

- GEBHARDT Logistic Solutions GmbH

- Dräxlmaier Industrial Solutions GmbH

- BMW Group

- Fraunhofer SCS

-

University of Applied Sciences Landshut (Production Management and Logistics)

The research and development project "iSLT.NET" is funded within the scope of the "PAiCE Digitale Technologien für die Wirtschaft" technology programme (project no. 01MA17006E) run by the Federal Ministry for Economic Affairs and Energy and is managed by the DLR project management agency „Gesellschaft, Innovation, Technologie - Informationstechnologien/ Elektromobilität" at the German Aerospace Center in Cologne.