Investigation of the Load Carrying Capacity Limits for Pitting and Wear on Wormgears to reduce the Test Duration

Research Topic

| Short Title | Flank Load Carrying Capacity of Wormgears |

| Start of Project | Q1/2021 |

| Funding | FVA-Nr. 920/I, IGF-Nr. 21391 N/1 Federal Ministry for Economic Affairs and Climate Action, BMWK |

| Contact | Dr.-Ing. J. Pellkofer |

Project Description

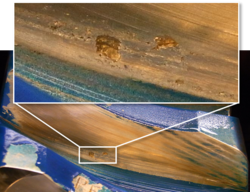

In this project, worm gears are to be investigated for their bearing capacity concerning pitting. As part of the investigations, a standardized method for determining the load carrying capacity of materials and lubricants is to be developed. The aim is to define a standardized and resource-saving test process for worm gears with regard to the type of damage caused by pitting. For this purpose, simulations of the pitting process and experimental investigations in single-stage tests on worm gears will be carried out. From this, a load-bearing characteristic value is determined for the pitting load carrying capacity of the material-lubricant pairing investigated. Running In and load collective tests are carried out using the results obtained this way. The results are documented in a guideline for conducting the tests. The procedure described in this way is applied in random tests to further material-lubricant pairings. Accordingly, the aim is to obtain load-carrying capacity values for the materials and lubricants investigated as a result of this procedure. At the same time, findings are to be generated on the scattering of pitting damage and on the behavior of crack initiation and crack growth. Based on the results of these investigations, a guideline for the resource-optimized performance of tests on worm gears is to be developed that can be standardized. The results can be applied directly by industry. Especially for small and medium-sized enterprises (KMU), which often have limited possibilities for carrying out tests to ensure safety, there are advantages and new opportunities in the development and testing of worm gear units. This leads to optimized gearboxes that offer competitive advantages through longevity and low backlash.