Department Laser Technologies

Joining and separating processes enable the cost-effective manufacture of complex products and implement innovations for lightweight construction, the production of mixed joints and functional integration. The Department Laser Technology is responsible for the investigation and further research of a representative range of joining and separation processes. The theoretical and experimental design of the processes, the integration of system technology as well as the implementation and realization of plant concepts form the center of these investigations. The work is accompanied by numerical simulation of the processes. In addition, modern concepts for process monitoring and data evaluation are developed and used to support process optimization.

Head of Department: Siegfried Bähr

The main research topics

Research Field: Laser manufacturing technology

The laser production technology at iwb deals with basic research on laser beam welding and uses modern system technology for process monitoring. With the help of new approaches to data processing, the sensor signals of process monitoring are used to systematically achieve process improvements.

Research Field Leader: Christian Geiger

Research Field: Intelligent Joining System Technology

Intelligent joining system technology represents an interface between the individual research areas in the Laser Technology group. Here, methods for data acquisition and evaluation are adapted and further developed for use in production technology. Modern data processing methods ranging from statistics to machine learning are used to provide practical recommendations for industrial implementation.

Research Field Leader: Tony Weiß

Find out more about the current projects here.

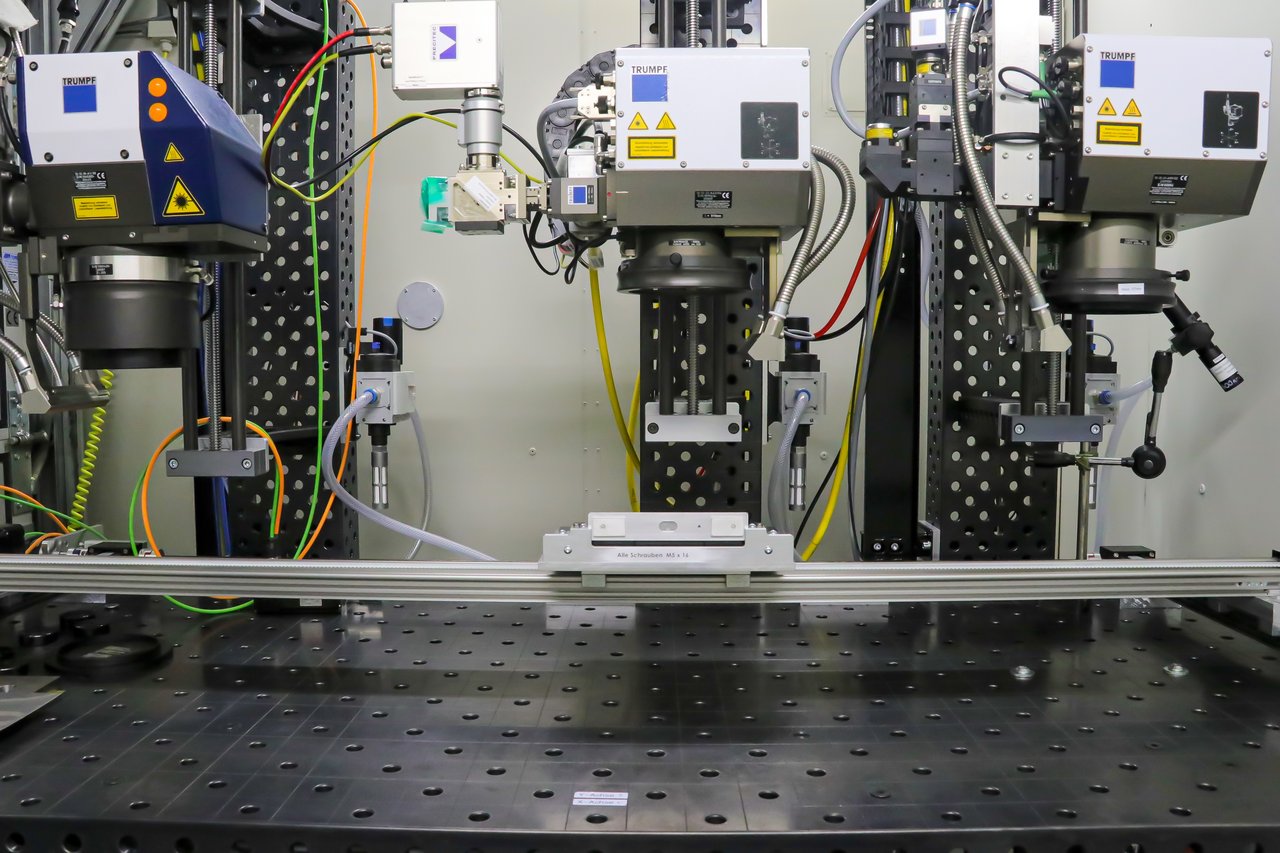

Equipment in the Department Laser Technologies

Laser system technology:

- Adjustable Ring Mode fiber laser (Coherent Pmax = 4 kW total power)

- Multi-mode fiber laser (IPG, Pmax = 8 kW)

- Multi-mode fiber laser (Coherent, Pmax = 8 kW)

- Multi-mode disk laser (Trumpf, Pmax = 4 kW)

- 2 Single-mode fiber laser (IPG, Pmax = 3 kW and 6 kW)

- Pulsed fiber laser (IPG, 100 W, 30 ns, 0.2 mJ)

- Pulsed fiber laser (Rofin, 20 W, 100 ns, 1 mJ)

- Pulsed fiber laser (Innolas, 25 W, 500 fs, 25 µJ)

- State-of-the-art fixed optics incl. options for tactile seam tracking and beam shaping, e.g.

- HighYAG Bimo

- Scansonic ALO3

- Precitec YRC, etc.

- Various scanner optics for remote processing, e.g.

- ScanLabIntelliWeld30

- Trumpf PFO33

- Precitec ScanMaster

- Scansonic RLW-A

- 6-axis articulated arm robot with various external kinematics

- Wire feeding system

- Flow boxes for CFRP processing

Sensor systems for process monitoring

- OCT sensors

- Photodiode sensors

- High-speed cameras

- Multispectral camera

- Optical microphone

- Pyrometer

- Laser line scanner

Modeling and simulation of joining and cutting processes

- Adina

- COMSOL Multiphysics

- MSC Marc

- Sysweld

- Hypermesh

- Matlab