TRR277 A02 – Particle-bed 3D printing by selective cement paste intrusion (SPI) – Particle surface functionalisation, particle synthesis and integration of WAAM reinforcement

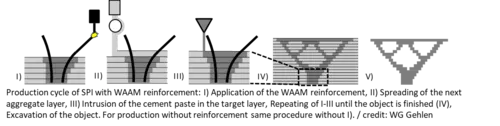

Within the scope of the joint research project with the Chair of Materials Science and Testing (TUM) and the Institute of Particle Technology (TUBS), the combination of two additive manufacturing processes for the production of concrete components with integrated reinforcement is being investigated. Wire and Arc Additive Manufacturing (WAAM) is used as an Additive Manufacturing process based on an arc welding technique. WAAM is combined with Selective Cement Paste Intrusion (SPI). The SPI process is a particle-bed-based additive manufacturing technology, in which aggregate is applied in thin layers and locally bound with cement paste.

Motivation

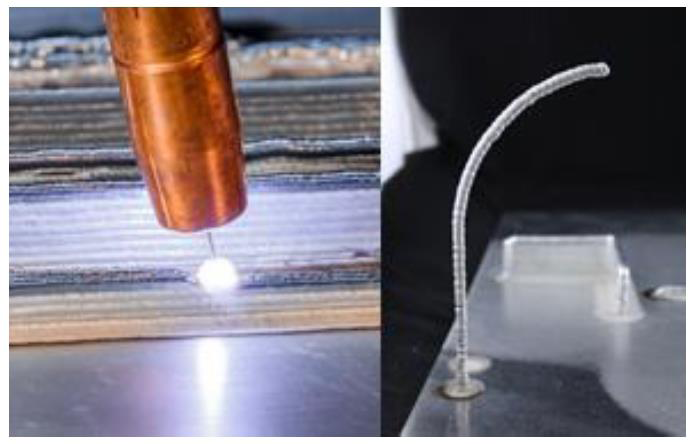

To enable the production of load-bearing reinforced concrete elements through SPI, the integration of reinforcement is necessary. The approach of this project consists of a hybrid fabrication of the reinforcement using WAAM simultaneously to the SPI process. WAAM is very well applicable for the production of large volume components with high build-up rates. The layer-by-layer manufacturing process enables a high degree of geometric complexity, allowing new shapes of steel reinforcement to be integrated into concrete components, e. g. force-flow-optimized structures.

Objective

For a combination of the SPI and WAAM processes, it is necessary to devise suitable cooling strategies to minimize the heat input into the particle-bed and the cement paste from the welding process. Simultaneously, the project partners are developing cement pastes and functionalizing new particles that can withstand increased temperatures during the production process.

Approach

At the beginning of the project, the iwb will identify suitable process parameters for the production of WAAM-manufactured reinforcement structures and conduct process investigations with an experimental set-up. Thereby, the cooling behavior of the manufactured reinforcement geometries will be analyzed by means of thermographic imaging. Based on this, the cause-effect relationships in WAAM of the steel reinforcement are quantified by regression analyses. Numerical process models are created to extend the understanding of the process. These models describe the temperature distribution in the WAAM-manufactured component and consider the influences of specifically cooled areas. Thus, a suitable cooling strategy can be derived theoretically and be validated, after integration into the experimental set-up.