TRR277 A06 – Laser Powder Bed Fusion (PBF-LB/M) of Steel Elements for Construction – Basics of Design and Mechanical Resilience

This project aims to explore and evaluate the factors influencing the manufacturing of safe and durable structural steel elements by Powder Bed Fusion of Metals using a Laser Beam (PBF-LB/M). In particular, the PBF-LB/M process, the post-treatment, and the geometrical aspects in terms of microstructure and mechanical properties will be investigated and correlations determined.

Motivation

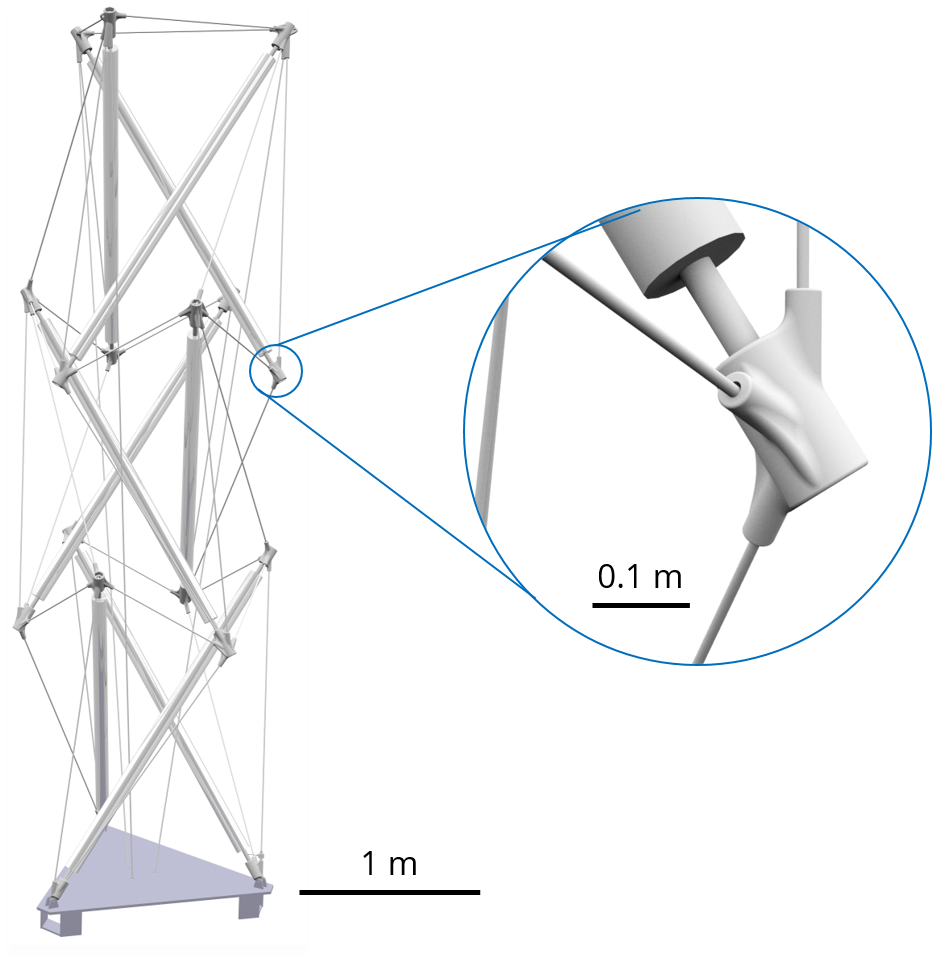

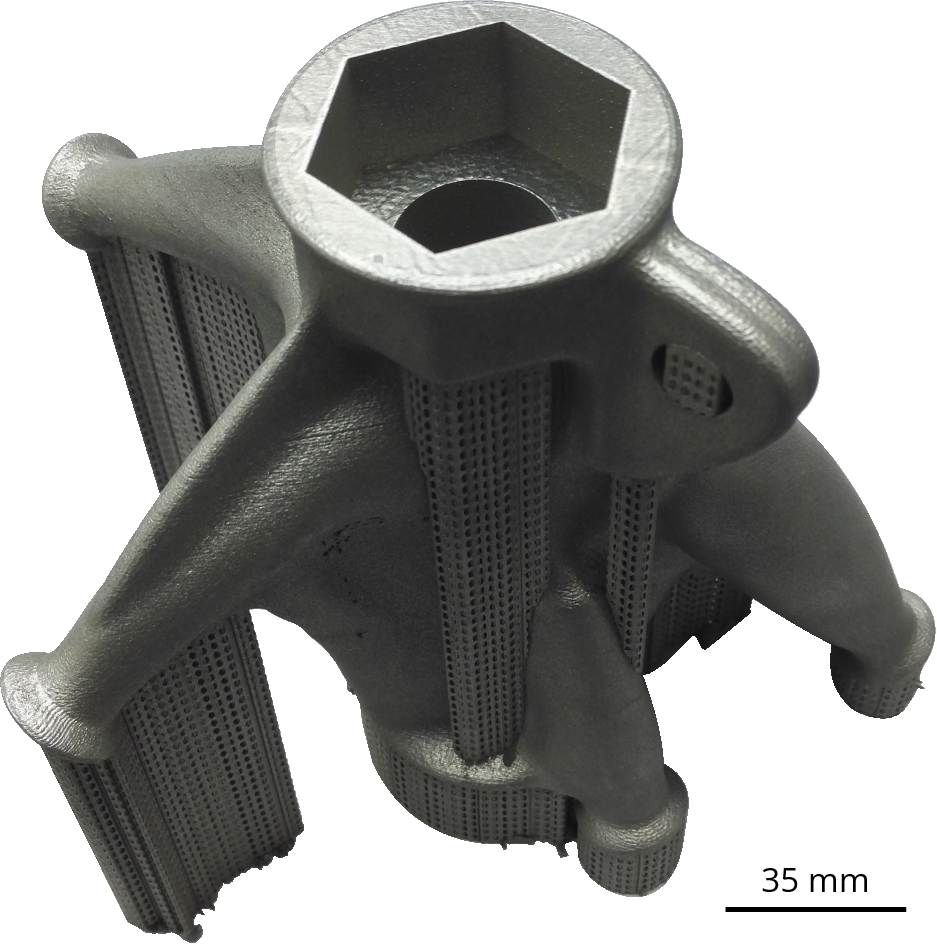

PBF-LB/M is one of the key technologies among metallic additive manufacturing processes. It enables highly complex structures to be manufactured very precisely directly from a digital design model. As a result, PBF-LB/M is already being used in series production in various industrial sectors. Due to its characteristics, LPBF also offers a high potential for the construction industry: Owing to the high degree of design freedom, the direct link between the real and digital world, as well as the economic efficiency at batch size one, additive manufacturing could revolutionize the construction industry. Hereby, the PBF-LB/M is particularly suitable for the production of elements for steel construction.

Objective

Until now, a precise prediction of defined mechanical properties of PBF-LB/M-manufactured steel elements is not possible. To establish the application of PBF-LB/M in the construction industry, civil engineering, and architecture, it is necessary to develop a methodology for the reliable production of durable structural steel elements by using

PBF-LB/M.

Approach

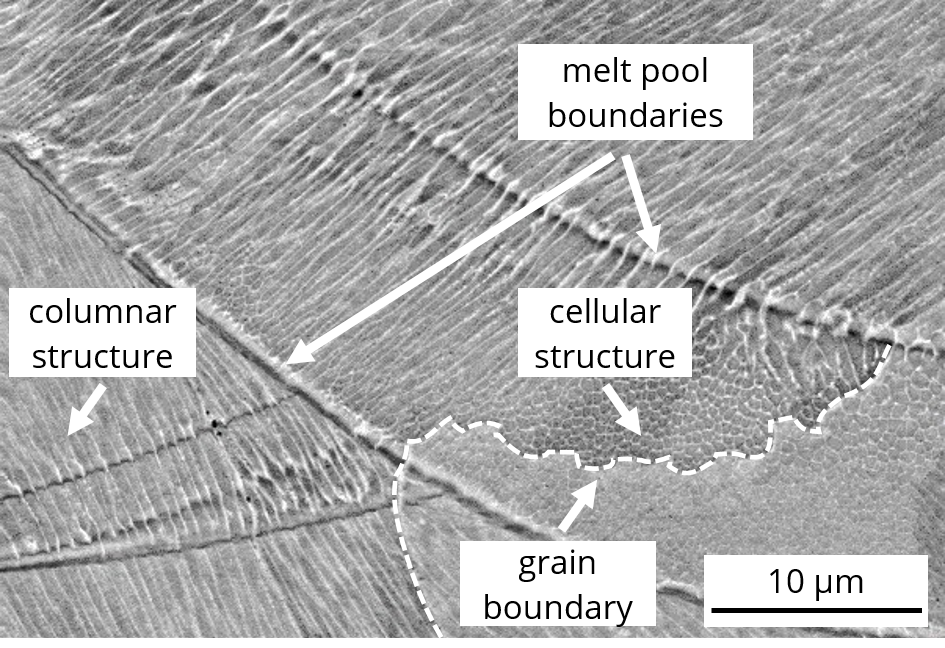

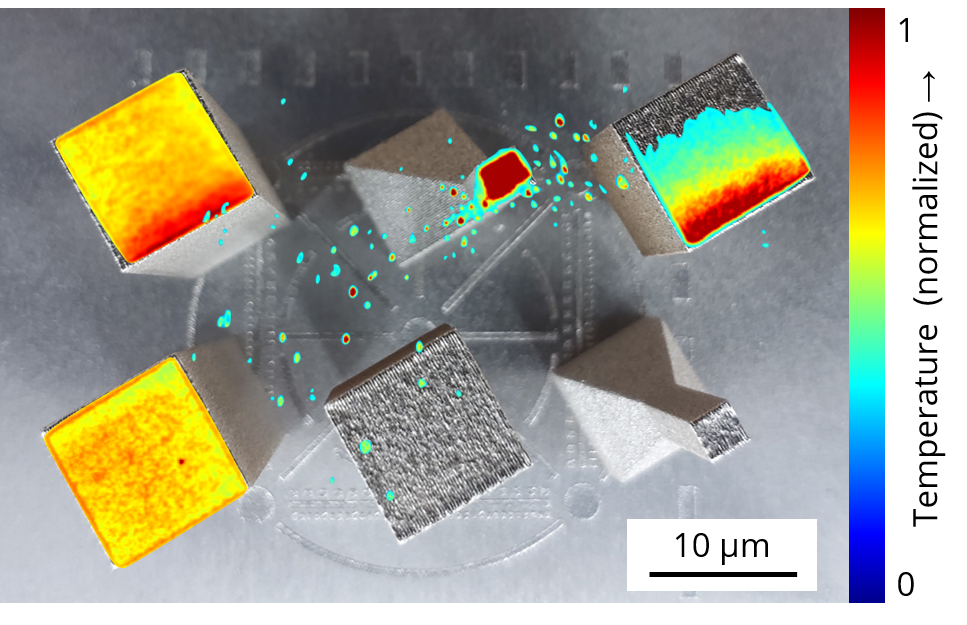

Initially, the influence of the process parameters on the cooling rates during PBF-LB/M is analyzed using in-process thermography. Besides, the effects of geometric aspects and post-treatments on the mechanical and metallurgical properties of the components will be examined. In the further course of the project, shape-optimized structural steel elements and large-scale components will be designed using the determined interrelations. Subsequently, the elements will be manufactured and tested under real operating conditions. Finally, a methodology for the economic and process-safe use of PBF-LB/M in the construction industry will be derived.

Results

In this research project, the relationships between process parameters, cooling rates, post-treatment and geometric aspects with the static and cyclic mechanical properties of PBF-LB/M -manufactured steel components are determined. Based on these findings, design recommendations will be derived to manufacture steel components with reproducible and defined mechanical properties using PBF-LB/M .