RoBerD – Robot-Assisted Visual Inspection in Disassembly

Remanufacturing existing products offers significant opportunities from both ecological and economic perspectives. Due to the high variety of product variants, the limited predictability of product returns, and the uncertain condition of returned products, the process has so far been carried out predominantly manually. In the long term, however, a purely manual approach is hardly economically scalable given high labor costs and a persistent shortage of skilled workers. A central process step is the visual inspection of disassembled product components (e.g., for wear), since this is when decisions are made regarding reuse and the necessary reconditioning steps. The RoBerD project therefore investigates whether this inspection process can be automated through the use of robotics.

Objective

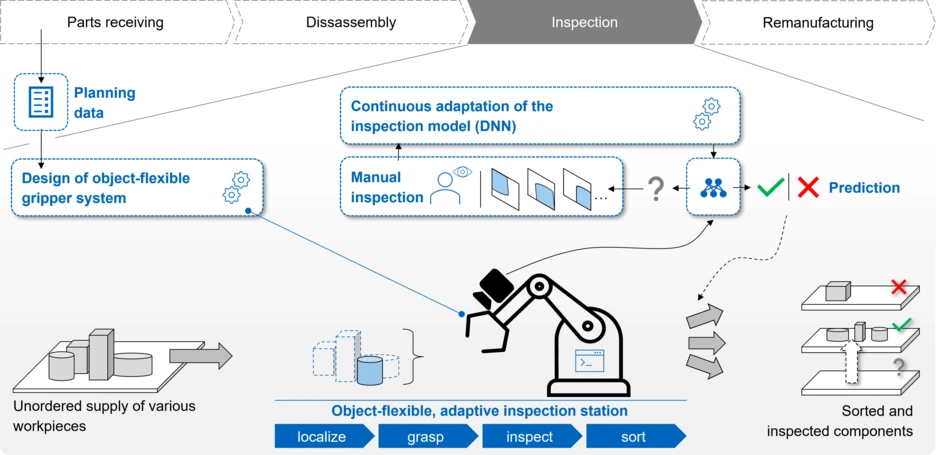

The aim of this research project is to develop a novel, object-flexible robotic system for the automated inspection of varying products and small batch sizes. After receiving the products, components are disassembled, cleaned, and fed to the inspection station in an unsorted state; they must be localized, grasped, and positioned for inspection. To this end, grippers are automatically designed from available product data (e.g., drawings, CAD) to cover a wide variety of parts. Camera-based AI determines the condition based on relevant image captures, and the overall system routes parts for reuse or rework. Predictions with high uncertainty are buffered, reviewed by personnel, and used for continuous model improvement. In this way, RoBerD addresses today’s automation hurdles, e.g. product variety, unknown defect patterns, and changing conditions, that conventional image processing cannot adequately handle.

Main research topics

- Object-flexible gripper systems

- AI algorithms for visual inspection

- Integrated system for robot-assisted visual inspection

Consortium

The consortium consists of three companies (Endutec Maschinenbau Systemtechnik GmbH, InstruNEXT GmbH, MAN Truck & Bus SE), two associated partners (J.M. Voith SE & Co. KG, XITASO GmbH) and the Institute for Machine Tools and Industrial Management (iwb) of the Technical University of Munich.

Acknowledgments

The Bavarian Ministry of Economic Affairs, Regional Development, and Energy funds the RoBerD project, and the VDI/VDE Innovation + Technology GmbH administratively supports the project consortium. The iwb thanks all partners for the funding, the support, and the excellent cooperation in the project.