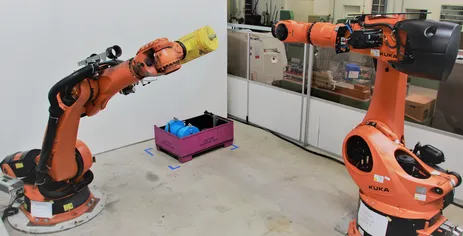

KIVI - Artificial Intelligence for Lifetime and Availability Prediction of Industrial Robots

The aim of the research project is the development of models for the classification and prognosis of damages of industrial robots.

With the help of these models, operators of industrial robots can identify damages of industrial robots before failure and avoid undesired machine downtimes. At the same time, developers of industrial robots can expand their product portfolios with attractive software products.

Machine learning methods are used to develop the models mentioned above. These are based on large amounts of data that contain information about the wear states of industrial robots. This explains the approach pursued in the KIVI project:

1. Acquisition of vibration and control data in different wear conditions of industrial robots through endurance tests. These data are collected both on test benches and under real production conditions.

2. Transformation of the data using methods of signal processing and Unsupervised Machine Learning

3. Training of Supervised Machine Learning models with the help of the prepared data

4. Integration of data acquisition and data preparation modules as well as the trained models into a software for fault classification and prognosis in production