partner links

News

Effective Lightweight Construction through ECAP of Aluminum Sheet Materials

Equal-Channel Angular Pressing

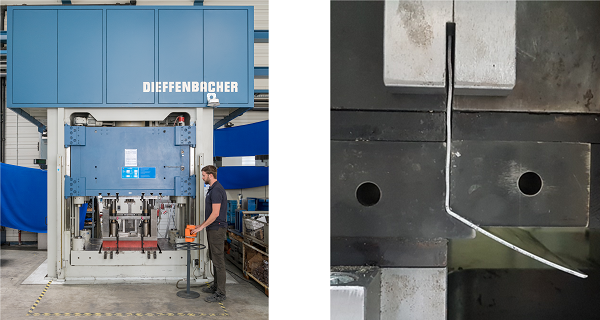

Equal-Channel Angular Pressing (ECAP) is a well-established method in research used to improve metals' mechanical properties using grain refinement. As the name suggests, ECAP involves pressing a blank through an angled die. The microstructure is strongly deformed by the generated shear stress and a finer microstructure is formed. While there is already profound knowledge about the ECAP of solid materials, there is little information about the effect of ECAP on sheet metal. However, the use of sheet materials enables an immense industrial potential for the process. Therefore, utg developed a die for the hydraulic Dieffenbacher press, which can perform ECAP tests for aluminum sheets and explore the process's fundamentals.

Right: In the ECAP Process, Sheets are Pressed through an Angled Die, where the Shear Stress Improves the Material Structure

Friction tests

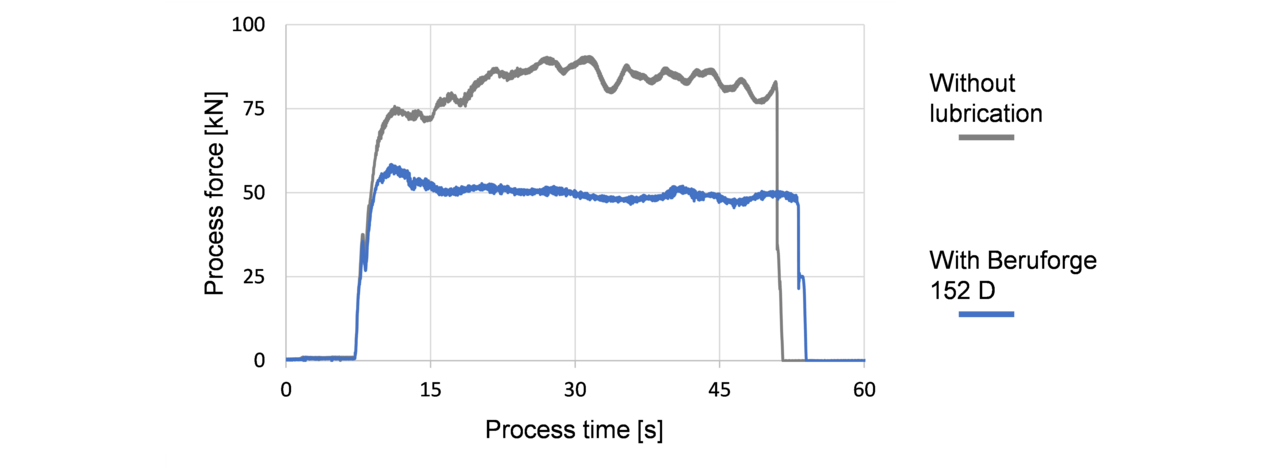

One of the main challenges arises due to the friction in the channel mold. If this is too high, it is easier for cracks on the sheet surface and for inhomogeneous microstructures to form. In cooperation with Carl Bechem GmbH, utg was able to remedy this by the targeted use of lubricants. By using the new coating lubricant Beruforge 152 D, the process forces could be reduced by more than 40%, in some cases, compared to unlubricated sheet metal. Furthermore, the process forces could be kept more constant by applying this lubricant, which results in a more homogeneous microstructure and better semi-finished product surface.

Promising results

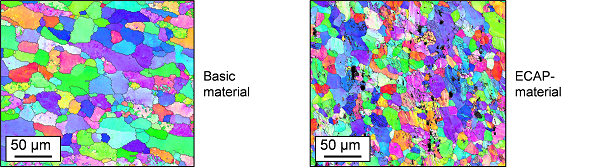

Tensile tests are currently taking place to investigate the semi-finished sheet's mechanical properties. Initial investigations already show a significant increase in the strength of the material. Also, crystallographic measurements are being carried out in collaboration with the Chair of Materials Science at the Chemnitz University of Technology to make statements about the material's structure and texture. The microstructural investigations show that smaller grains and more complex structures are present in the ECAP state, which impede the sliding of the metallic lattice planes and thus result in higher strengths.

Right: Microstructure of the material processed by ECAP. One can see the smaller grains with a more complex structure.