Semi-finished sheet metal products are often subjected to various process steps (cutting, bending, stamping) in succession in progressive dies. Since the individual process steps are mechanically interconnected, all tools operate at the same speed. The overall speed is consequently determined by the slowest step. This is a compromise that is usually made at the expense of output rate and quality.

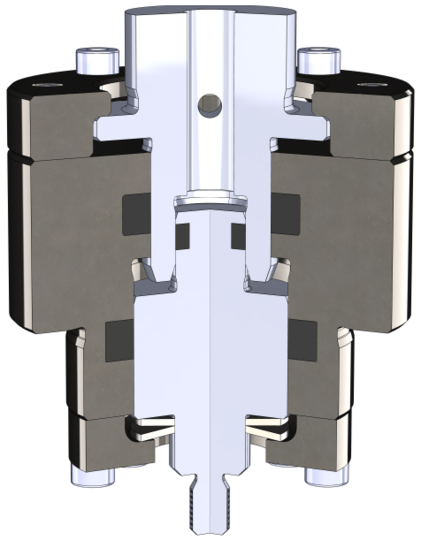

This challenge was addressed by a team of researchers at utg. As part of a two-year project funded by the EFB, they investigated how the ram speed of individual active elements can be specifically adapted to the optimum speed for the specific process. With the development and design of the hydraulic path-speed converter (KEKS), a speed reduction of up to 60% is possible, resulting in a significant improvement in the quality of the forming for specific applications.

Thus, the project could be successfully completed and our KEKS was even registered for a patent via the Bayerische Patentallianz GmbH:

COMMERCIAL OPPORTUNITIES

The standard component (patent pending) adjusts the active element speed of individual production steps to match the optimum speed of the production process.

The advantages of the KEKS:

- Improved quality with higher output

- Increased efficiency of the entire tool

- Reusable standard component (normalcy)

DEVELOPMENT STATUS

The process is patent pending in Europe and the USA. The proof-of-concept was successful and the further development was funded by the German Federal Ministry of Economics with 200,000 Euros. Today, a close-to-production, fully functional prototype exists.