DFG Funded Project about Elastic Deformation Behaviour

For several years, utg and the Munich Research Reactor (FRMII) team have been working closely together. Currently, a cooperation project funded by the German Research Foundation (DFG) is in progress.

This project investigates the elastic deformation behavior of forming steels. Here fundamental research of the macroscopic and microscopic material parameters is determined and correlated to improve existing models for the FEM simulation. For this purpose, one performs uniaxial cyclic tensile tests to determine the macroscopic force, strain, and sample temperature. These measurements are taken parallel to the microscopic strain and dislocation density recordings.

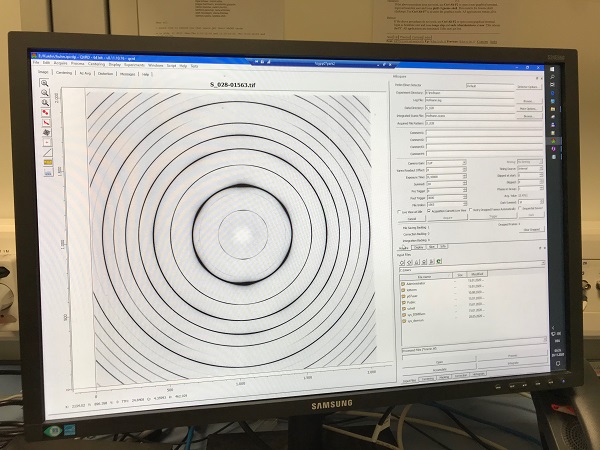

In addition to neutron diffraction, which can be performed at FRMII in Munich, high-energy X-radiation tests performed at DESY's in Hamburg also offer the possibility to measure microscopic parameters. X-radiation has some advantages over neutron radiation, such as a faster measurement frequency, which results in readings from DESY being very beneficial for utg and FRMII scientists.

Tensile Tests at the DESY

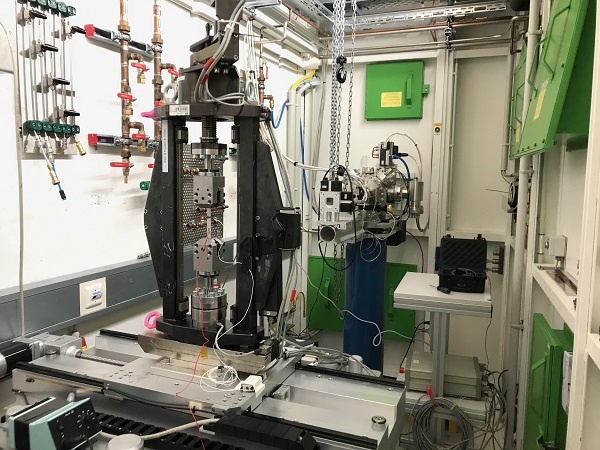

The DESY team provided TUM scientists with a set amount of time for measurements at the Petra III measurement instrument from 17-21 November 2020.

The tensile test stand of FRMII, which was dismantled in Munich and rebuilt in Hamburg, served as the test bench. The experimental setup and the measurement procedure at DESY allowed X-ray transmission measurements during a continuous, quasi-static tensile test. In this way, it was possible to record X-ray diffraction profiles synchronously to macroscopic parameters.

Measurements in 24-hour Shift Operation

To use the precious measurement time as effectively as possible, the scientists worked around the clock in shifts and investigated a wide variety of test methods and measurement settings. Thus, in addition to the necessary investigations, further preliminary tests were carried out for a planned research project in the field of superplastic forming. Furthermore, tensile tests were carried out at DESY to shed light on the forming process's underlying mechanisms and thus draw conclusions about industrial applications.

Promising Results Achieved

In total, the scientists did about 65 tests, and initial results show that the measurements are of great value both for the ongoing research project and for the future planned research project. Due to the complexity of evaluating the diffraction profiles and the enormous amount of data, a detailed evaluation will still take some time.