There exist a variety of different transport vehicles for the multitude of possible transport units and transport processes. In this project we will focus on transport systems that consist of a combination of automated guided vehicles (AGV), tugger trains and lift trucks. The level of investment for such systems depends not only on the number and type of the deployed vehicles but also on the required infrastructure, such as charging technology, tugger train stations etc. Appropriate comparative analysis methods are missing in the literature. This leads to uncertainties in the planning process, which may result in chosing a cost-intensive solution.

Due to the various aspects of the transport vehicle types, the corresponding planning approaches differ in methodology and underlying assumptions. A comparative method based on those approaches is hence inaccurate and often associated with suboptimal solutions. Furthermore, simultaneously applying different approaches is error-prone, time-consuming and requires expert knowledge.

In summary, there exist no holistic approaches for a comparative dimensioning and evaluation of transport systems.

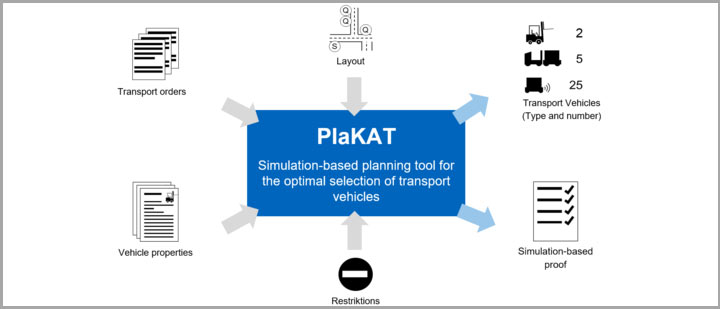

The main objective of the research projekt “PlaKAT” is the development of a holistic approach for a comparative dimensioning and evaluation of transport systems, which consist of a combination of the transport vehicles tugger train, AGV and Forklift.

Based on this approach, we then develop a generic simulation-based tool, which supports the designer during the general planning stage in defining the optimal Transport system under a specific set of constraints. The obtained solution include the number of every vehicle type as well as the transport orders associated with each type. The developed procedure provides also a simulative proof of the overall performane of the system with consideration of the internal interactions.

Further, the implemented tool can be applied for systems already in operation. In doing so, potential improvements might be detected. This is especially relevant, when the initial constraints such as Layout or order structure have changed over time.

Work packages (WP) 1 and 2 deal with the analysis of the considered transport vehicles with respect to their characteristics as well as to the methods used to determine their performance.

Building on the identified methods in WP 2, we will then develop a simulation-based planning approach for selecting the optimal transport system in WP 3.

The input data as e.g. layout, transport orders etc. will be formalized in WP 4 in order to be later used in the generic simulation model, which will be subsequently implemented in a discrete event simulation environment (WP 5). In WP 6 an evaluation of the developed planning tool by the means of example scenarios will be conducted.

Work package 7 deals with the the documentation and the transfer of the results.

- BMW Group

- CROWN Gabelstapler GmbH & Co. KG

- GEBHARDT Logitic Solutions GmbH

- GEV Großküchen-Ersatzteil-Vertrieb GmbH

- HAWE Hydraulik SE

- io-consultants GmbH & Co. KG

- Jungheinrich Logistiksysteme GmbH

- KION Group

- LR Intralogistik GmbH

- Ludwig Meister GmbH & Co. KG

- Miebach Consulting GmbH

- PROTEMA Unternehmensberatung GmbH

- PSI Logistics GmbH

- ROI Management Consulting AG

- SAFELOG GmbH

- Serva Transport Systems GmbH

- Staudinger GmbH

- Weissenborn Logistik-Consulting

This research project is carried out under the number 20959 N/1 on behalf of the Research Association for Intralogistics, Materials Handling and Logistics Systems e.V. and is funded by the Federal Ministry of Economics and Technology through the German Federation of Industrial Research Associations "Otto von Guericke" e.V. (AiF).