The widespread acceptance of e-commerce makes it easier for wholesalers to reach end customers directly, which means that wholesalers are increasingly shifting their business from business-to-business (B2B) to business-to-consumer (B2C). End-customer orders are characterized by the fact that they order in small units and expect fast and error-free delivery, which increases the number of shipments and delivery time requirements. Since automated material handling systems enable high throughput, short lead times and high process quality, these requirements can be met well with these systems. It is therefore to be expected that these systems will experience an increasing demand and therefore have to be planned efficiently.

Automated material flow systems consist of standardized conveyors which are assembled to a customer-specific system (see Figure 1). Customer-specific design of the systems is necessary because existing building structures have to be taken into account, customer-specific processes have to be implemented and upstream and downstream systems and work steps have to be integrated. The project planning of these customer-specific plants is always in the context of cost and time pressure, whereby it is essential to create the plant control software quickly and in high quality. The challenge here is to master a large number of different conveyors with individual sensors and actuators and to integrate them correctly into the plant control system. This results in the problem of efficiently creating the control software for customer-specific systems.

The goal of the aComA project is to optimize the process of creating the control software. To this end, a model-based methodology for the creation of control software is developed using reusable software modules. These software modules are combined and parameterized to create the customer's individual layout in order to generate the individual control software. This method also reduces the time required to create the control software and increases the quality of the control software (few errors).

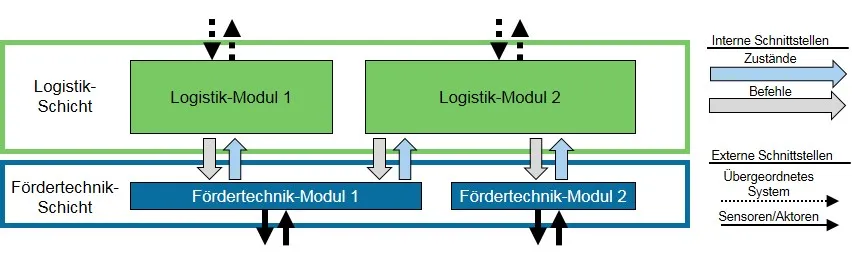

In order to be able to efficiently create the control software for automated material flow systems, a custom-fit architecture is developed for these. This results in the two-layer architecture, which separates the control of the conveyors from the decisions of the material flow, resulting in two module classes: Conveyor modules and logistics modules (see Figure 2). For these modules, a generic control algorithm is developed that determines the structure of the methods and interfaces between the modules. This generic control algorithm is thus a template on the basis of which specific modules are worked out. This template enables the modules to be worked out independently of each other and still ensures that the modules are compatible with each other.

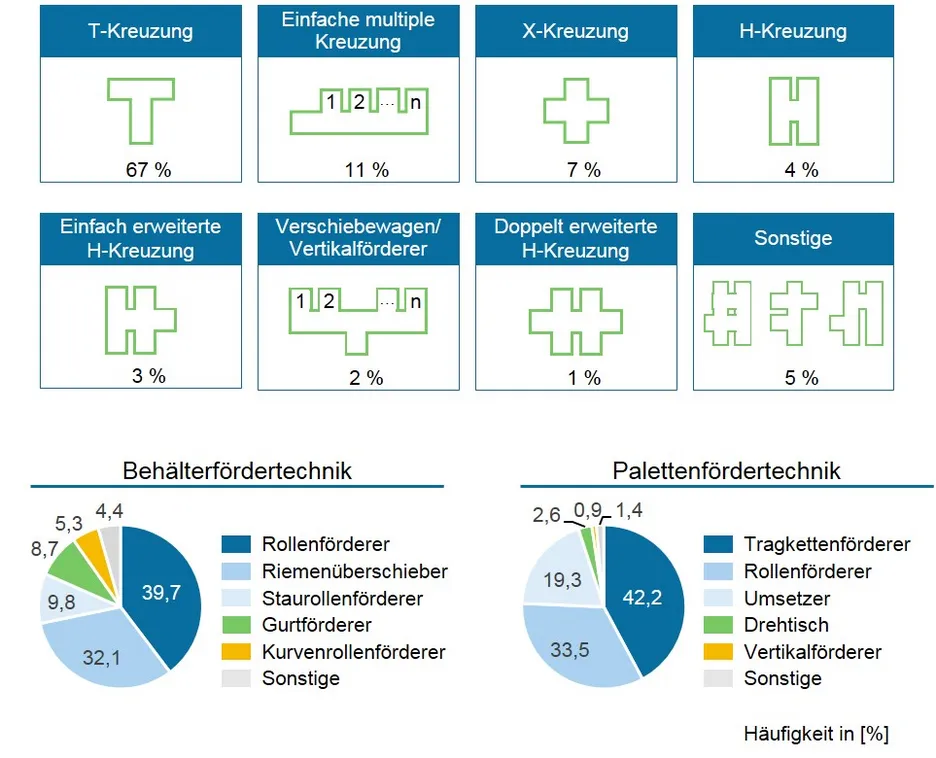

Then, layouts are used to analyze which conveyor and logistics modules are most commonly used in automated material handling systems. The result of this analysis is that seven types of crossings cover 95% of crossings and only 5% of crossings are individual crossings (see Figure 3). A similar picture emerges with regard to the conveyor technology modules: With 5 types of conveyors, 95.4% of the conveyors are covered in the case of container conveyor technology and 98.5% in the case of pallet conveyor technology (see Figure 4). In addition, the most frequent handling devices were contour control (42%), scales (17%), automated magazines for pallets and containers (16%) and skid and foot clearance control (12%). The remaining 13% of the handling devices are distributed among other devices, e.g. document beigeers, labellers or pallet wrappers.

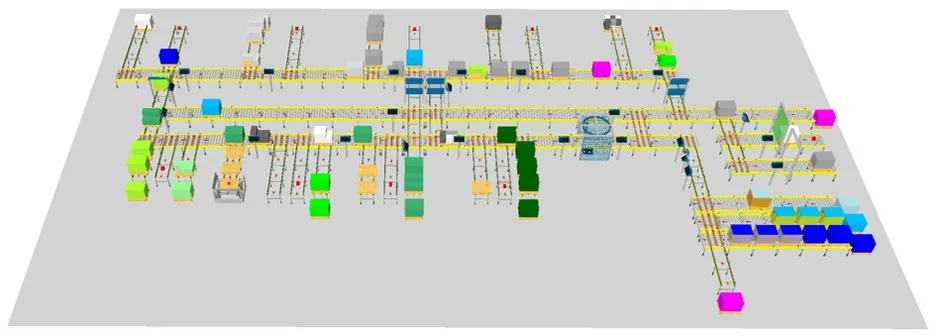

These frequently occurring modules are then developed using the generic control algorithm, resulting in a basic library for automated material flow systems. With the modules of this library, the control software for the typical structures of material flow systems can be implemented, and in addition, the generic control algorithm ensures that this library can be extended by project-specific modules. The functionality of the developed modular concept of the control software is then demonstrated by means of an extensive industrial layout of the pallet conveyor technology in an emulation environment (see Figure 4).