Keywords

Structural Health Monitoring, Predictive Maintenance, Machine Learning, integrated sensors, CFRP rim

Problem

The mass and rigidity of vehicle rims have a great influence on important dynamic properties and fuel consumption. Since rims are also particularly relevant to safety, the lightweight design potential is often not exploited. High safety factors against design failure lead therefore to weight increases.

Goal

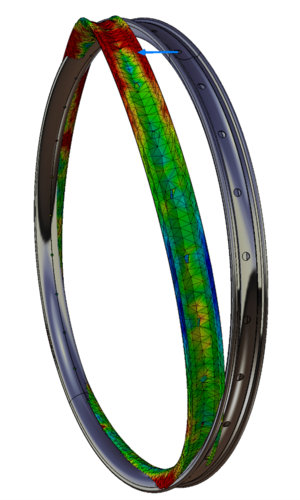

In order to avoid high safety factors, damages shall be assessed and detected in a new type of lightweight wheel with an integrated sensor system. As part of the ProVeS research project, a CFRP lightweight rim with integrated sensors and appropriate data analysis is to be designed and optimized. The design of the shape and laminate must consider the limitations caused by the manufacture and integration of a sensor system. The final sensor system has to be integrated in such way that any form of critical damage can be detected using measurement data.

Approach

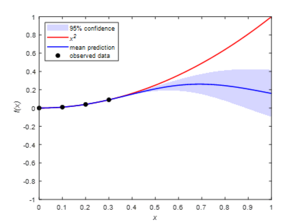

By comparing FEM simulations of the defined load cases of both undamaged and pre-damaged rims, an optimal sensor arrangement is to be determined. Measurement campaigns validate the simulations on the one hand, and on the other generate training data for the machine learning algorithms.