Additive design and manufacturing

Research group

Our Motivation

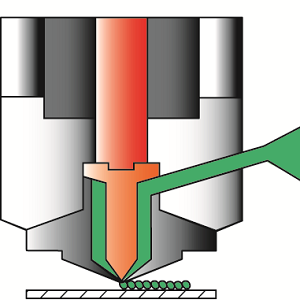

One focus of the research group is the development of droplet generators for 3D printing. These processes use fluids in the high temperature range (up to 800 degrees Celsius) and with very high viscosities (103 to 109 Pa s). Next to the realization of these systems, efficient development processes are conceptualized.

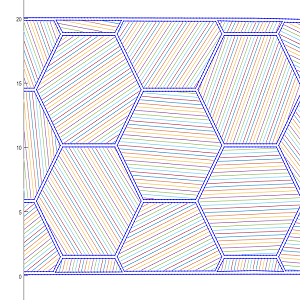

The printing quality of RP systems not only depends on the hardware being used, but is also greatly influenced by tool path planning strategies for the printing of contours and filling patterns. Therefore one goal is the development of efficient G-Code, to optimize the printing strategy in respect to the properties of the building material.

Methodology

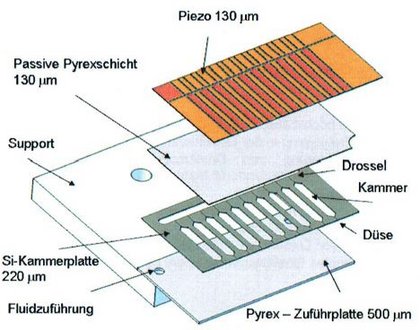

The approach for the development of systems which lead to finished products is the early setup of functional models. These are used for the calibration of minimalistic models, which are used for the optimization of system functions. For the manufacturing of these microsystems, alternative processes to microelectronics are employed. In order to avoid time and cost intensive manufacturing processes like anisotropic etching or high numbers of lithography steps for example, laser ablation, wafer sawing and anodic bonding are used.

For the development of suitable filling strategies during the conversion of STL files to G-Code, the MiMed developped Matlab library SG-Lib is employed. It allows a modular structure of functions, which enables fast development and efficient testing.