Project description

The development and design of complex material flow systems is time-consuming and expensive, hence a specific approach for configuring complicated customized systems out of predesigned modules is needed in order to reduce the development effort, increase quality and use the economy of scale. Nowadays, the control software required for an internal logistics system is often not modularized. This leads to further increases in effort for project planning and implementation as well as for customizing a system, e.g. adding or removing components, after commissioning. This manual activities lead to a high development effort and require valuable, highly skilled manpower for recurrent, costly and error-prone activities.

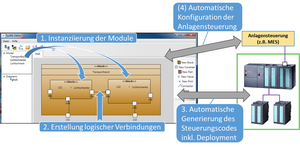

The aim of this research project is the automated generation and configuration of control software for modular systems in the domain of intralogistics systems. Based on a model-based approach, a method to integrate the relevant descriptions of conveyor modules, software modules and automation hardware to generate and configure control software automatically should be developed. Storing the modules in a library to reuse the model descriptions can significantly reduce the development effort for the control software. To assist the user in the field of the material flow handling optimally, a layout-oriented modeling methodology will be developed.

Industrial partner:

- SSI Schäfer GmbH

- 3S-Smart Software Solutions GmbH

- Jungheinrich AG

- Mewes & Partner GmbH