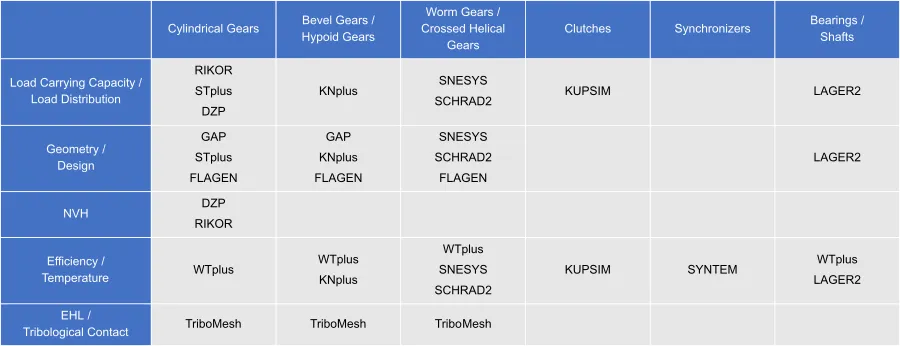

The Gearbox Dimensioning Software GAP allows an initial design of gearboxes.

The Cylindrical Gear Program STplus can be used to calculate cylindrical gears' gear geometry and load capacity according to DIN/ISO 6336, AGMA, and many other calculation methods.

Using of the Flank Generator FLAGEN, any gear geometries can be generated.

The program Efficiency and Temperature Balance WTplus determines the efficiency and thermal balance of any manual, automatic, and industrial gearboxes.

The program Pinion Modification RIKOR allows the calculation of shaft deformation, bearing deflection, tooth flank corrections, load distribution in tooth contact, damage-relevant stresses, and contact pattern for spur, helical, and double helical gears.

The Dynamic Tooth Load Program DZP calculates transmission errors, force excitation, natural frequencies, and additional dynamic forces in spur and helical gears.

The Bevel Gear Standardization Program KNplus enables bevel gear geometry and load capacity calculation according to DIN 3991 and other methods.

The Helical Gear Calculation Program SCHRAD2 can be used to calculate gear geometries and tolerances for helical gear pairings as well as gear forces, resulting bearing forces and speed ratios in tooth contacts.

The program group SNESYS includes various programs for designing and recalculating worm gears.

The Rolling Bearing Program LAGER2 calculates the rolling bearing stiffness (internal loads and pressures) and the (modified reference) bearing life according to DIN ISO 281.

Taking into account the heat dissipation through the oil, KUPSIM calculates the temperature balance in multi-plate clutches/brakes for individual friction phases as well as cooling phases collectively.

The program SYNTEM calculates the temperature development in a manual transmission synchronization during a shift. Internal, external, double or three-cone synchronizations can be calculated with a largely free choice of friction surface structure/geometry.

The program TriboMesh is used for the numerical calculation of fluidfree and lubricated rolling and sliding contacts using multi-physics simulations.

In addition, computational investigations are carried out by means of simulation using the finite element method (FEM), computational fluid dynamics (CFD), and multiphysics.

There is close cooperation with FVA GmbH for the development of the simulation and calculation programs. Calculation programs created on behalf of the FVA are collected and checked in the FVA Workbench and are available to FVA member companies. Some important programs of the FVA were developed at the FZG. They enable the design and simulation of different machine elements and systems and are recognized and widely used in the industry.