Worm Gears

Worm gear units can realize high gear ratios in a single stage. This results in comparatively sizeable longitudinal tooth slippage, reducing efficiencies compared to spur gear units. Due to the significant overlap, worm gear units are low-noise and low-vibration. Self-locking and self-braking are possible through the appropriate selection of the gear geometry. The use of worm gears as power gears is usually limited by wear or pitting and power loss. Material pairings other than the conventional steel/bronze pairing are more vulnerable to scuffing.

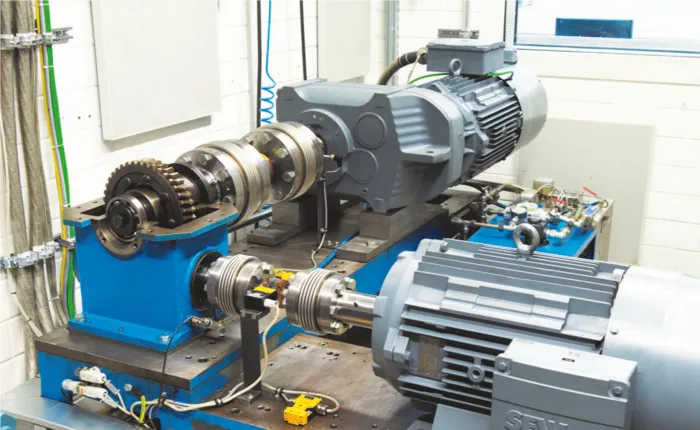

To determine the sliding wear, pitting, and scuffing load capacity of common worm gear bronzes and brass, gray cast iron, and nodular cast iron, a total of 5 partly electric, partly hydrostatically braced test rigs are available.

The results are presented as specific wear or scuffing damage as a function of output torque or as pitting growth versus a number of load cycles. The high sliding components in worm gears cause more significant power losses with increasing transmission ratios.

With torque-measuring shafts, efficiency measurements can be carried out for each operating condition. The tooth root load-carrying capacity of worm gears is determined in pulsator tests. A unique device has been developed for this purpose, which allows the worm gear teeth to be loaded via the associated worm shaft.