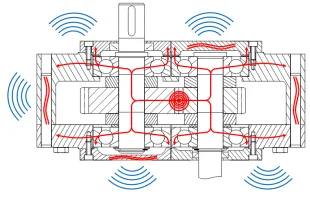

Additional internal dynamic forces occur in the running gear unit, which changes the tooth stress and influences the noise behavior of the gear unit. Noise behavior is becoming increasingly important due to growing demands for comfort. The additional dynamic forces must therefore be taken into account in the development of high-performance transmissions. Experimental and theoretical investigations are used to determine these additional dynamic forces' magnitude and influenceability and verify and further develop analytical calculation models for simulating excitation and vibration behavior. In the dynamics test rig for cylindrical gears, piezoelectric accelerometers are used to measure the torsional and bending vibrations on the gear body.

In addition, airborne noise and structure-borne noise can be measured on the gear housing. The stiffness of the meshing teeth is of decisive importance for the computational determination of the internal dynamic forces, the load distribution over the tooth width, and the load distribution over several meshing tooth pairs.