Cylindrical Gears

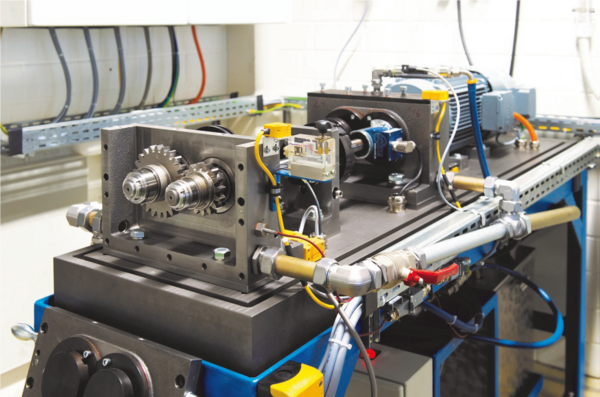

Cylindrical gears are the most widespread transmission types. The fatigue life of cylindrical gears is limited by pitting, micropitting, scuffing, wear, tooth root breakage or tooth flank fracture. The basis for the experimental examination of these gear damages is the standard FZG back-to-back gear test rig, which was developed by FZG and is used all over the world.

In this test rig concept, test pinion and wheel are fixed to two parallel shafts, which are connected with a gearbox of the same gear ratio at the other end. The decisive advantage of this back-to-back concept is the relatively small power input of drive motor, even for high testing output.

The described types of damages, as well as material, lubricant and efficiency examinations for external and internal gearings can thereby be carried out very efficiently. Gearings with a center distance up to 200 mm and a module up to 12 mm can be tested with the FZG back-to-back gear test rigs. Gears with a module range from 0.3 to 1 mm, which are used in the areas of robotics, microsystems and medical technology, can be tested with special small gear test rigs.