Synchronizers

In vehicle manual and DCT transmissions, the gears are changed by the actuation of tooth clutches. Synchronizers are used to realise equal rotational speed in the dog clutch, which is necessary for convenient gear shifting. The requirements for synchronizers are application-specific and cover a large spectrum. Besides a high torque transfer capability and related high energy and power density for the friction material and the lubricant, low wear and high long-term stability of the friction behaviour, as well as convenient gear shifting are important development objectives.

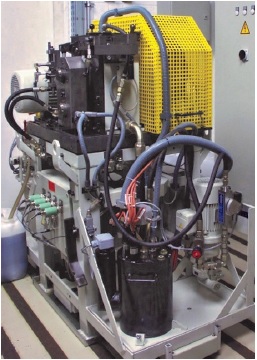

Examinations of friction, wear and service life behaviour of synchronizers are carried out with the FZG standard synchronizer test rig ZF/FZG SSP-180. Entire serial production synchronizer packs with various designs can be integrated in the test rig. Within the scope of systematic life-cycle analysis, the influences of the lubricant, mechanical stress and material combination on the fatigue life are examined.

Furthermore, knowledge of the frictional behaviour of the synchronizer’s cone clutch and its dependency on the influencing parameters is a fundamental requirement to optimise of the synchronizer. This is explained with the tribological characteristics in the frictional contact, which influence the design of the blocking mechanism, as well as function, shifting comfort, service life and drag loss behaviour of the synchronizer.