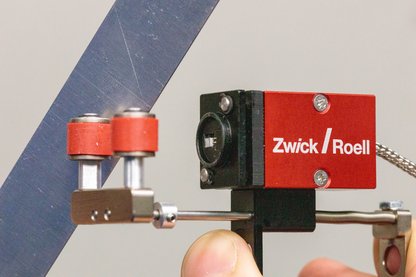

| Manufacturer | ZwickRoell GmbH & Co. KG |

| Model | Tsens (prototype) |

Brief Description:

The ZwickRoell Tsens is a clip-on sensor that can be applied directly to a flat tensile specimen during the uniaxial tensile test. The specimen surface temperature is measured via a platinum resistance thermometer (PT1000). The sensor can be connected directly to the TestControl of the ZwickRoell AllroundLine Z 150 universal testing machine.

Technical Specifications:

| Specimen Shape | Flat tensile specimen |

| Specimen Thickness | 0 ... 20 mm |

| Temperature Measurement | Relative temperature change in °C |

| Measurment Type | Contact |

Main Areas of Application:

- Determination of characteristic values in materials

- Thermal determination of the onset of flow

Photo Gallery:

Brief Description:

The thermocouple is a pair of metallic conductors made of different material, connected at one end and suitable for temperature measurement due to the thermoelectric effect. In principle, the thermocouple provides electrical energy from the heat at a temperature difference along the electrical conductor. The electrical voltage occurring at the metallic conductors' ends is comparatively small and ranges from a few 10 µV per 1 °C temperature difference. Even at high-temperature differences above 1000 °C and selected materials with high sensitivity, the achievable electrical voltages are below or in the order of magnitude around 0,1 V.

Technical Specifications:

| Most Commonly Used Model | Thermocouple type K (class 1) |

| Wire Diameter | Ø 0,5 ... 3 mm |

| Interface | HBM Spider 8, utg-measurement box (own design) |

| Measurement Type | Contact |

| Messart | Berührend |

Main Areas of Application:

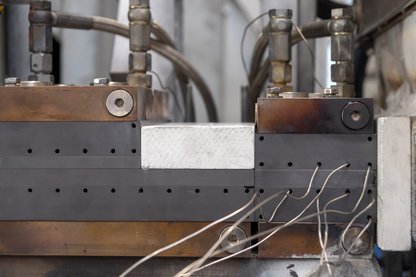

- Temperature control during casting

- Temperature control during a high-temperature tensile test

Photo Gallery:

Brief Description:

Resistance thermometers are electrical components that exploit the temperature dependency of the electrical resistance of an electrical conductor to measure temperature. Pure metals are the preferred choice for resistance materials. They show more significant resistance changes than alloys. Furthermore, they have an almost linear relationship of resistance to temperature. For reliable measurements, corrosion-resistant platinum is the preferred material because it shows minimal aging and can manufacture thermometers with a low tolerance range.

Technical Specifications:

| Most Commonly Used Model | PT 1000 (type A or B) |

| Dimensions | 2,1 mm x 2,3 mm |

| Measuring Range | -70 ... 500 °C |

| Connection | Solder pins |

| Basic Resistance | 1000 Ω |

| Temperature Coefficient | 3850 ppm/K |

| Interface | HBM Spider 8, utg measurement box (own design) |

| Measurement Type | Contact |

Main Areas of Application:

- Determination of material characteristic values

- Measurment of the specimen temperature

| Manufacturer | Micro-Epsilon |

| Model | thermoMETER CT |

Brief Description:

Infrared pyrometers are designed for a wide range of non-contact temperature measurement applications. They can measure temperatures in melts and blast furnaces precisely and reliably. Thanks to the compact design of the infrared pyrometers, they are often integrated into applications with limited installation space, e.g., in mechanical engineering, small apparatus construction, or OEM applications with multiple infrared measuring points.

Technical Specifications:

| Measuring Range | 150 ... 950 °C |

| Spectral Range | 8 ... 14 µm |

| Measurement Type | Contactless |

Main Areas of Application:

- Temperature monitoring during material characterization

- Temperature measurement during forming tests

| Manufacturer | InfReC |

| Model | Thermo Gear G120EX |

Brief Description:

The thermal imaging camera "Thermo Gear G120EX" is a thermography device that is mainly used portably but can also be implemented as a stationary camera. A thermal imaging camera (also referred to as a thermographic, thermal, or infrared camera) is an image-producing device similar to a conventional camera, the difference being that it receives infrared radiation. Infrared radiation is in the wavelength range of approximately 0,7 µm to 1000 µm. However, thermal imaging cameras use the spectral range of approximately 3,5 to 15 µm (mid-wave and long-wave infrared) due to this range contains the typical emission wavelengths near ambient temperature. This range is also suitable for measuring and visualizing temperatures in the ambient temperature range if the emissivity is known. However, depending on the material, this emissivity can vary greatly; between 0,012 and 0,98, the temperature assignment can be correspondingly inaccurate.

Technical Specifications:

| Measuring Range | -40 ... 1500 °C |

| Resolution | 0,04 °C |

| Camera | 320 x 240 pixel |

| Spectral Range | 8 ... 14 μm |

| Frame Rate | 60 fps |

| Measurement Type | Contactless |

Main Areas of Application:

- Temperature measurement of tools

- Temperature measurement during forming tests