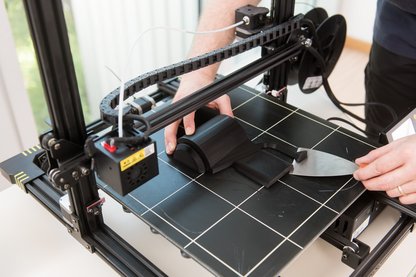

| Manufacturer | Anycubi |

| Model | Chiron |

| Year of Production | 2019 |

Brief Description:

The Fused Deposition Modeling (FDM) process finds use at utg for the flexible, additive manufacturing of foundry models, demonstration objects, and the adaptation of test set-ups. Depending on the area of application, printed filaments are made-up of PLA, ABS, and PETG. The high flexibility in the design, the modification of geometries, and the rapid availability of the models, usually printed overnight, make the 3D printing process a valuable addition to research in industry-related subject areas.

Technical Specifications:

| Technology | Fused Deposition Modeling (FDM) |

| Construction Volume | 400 mm x 400 mm x 450 mm |

| Extrusion Width | 0.2 ... 0.8 mm |

| Layer Thickness | 0.05 ... 0.3 mm |

| Positioning Accuracy | x/y 0.0125 mm; z 0.0020 mm |

| Printing Speed | 20 ... 100 mm/s |

| Materials | ABS, PLA, PETG |

Main Areas of Application:

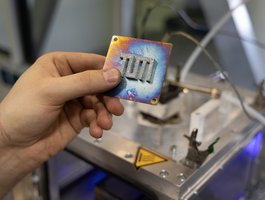

- Foundry models

- Test parts

- Objects of interest

- Functional models

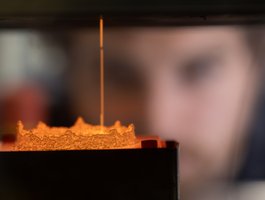

Photo Gallery: