| Manufacturer | Demag Technica |

| Model | 30/10 D I MCP N |

Brief Description:

The Demag Technica 30/10 D I MCP N, a continuous casting machine, is a pilot machine that allows the processing of metallic materials into semi-finished products on an academic scale. Technically, the machine corresponds to industrially used continuous casting plants. The machine can rotate so that one can cast horizontally, inclined, or vertically. The integration of continuous casting dies is mostly variable. Usually, one uses sliding molds based on stationary graphite molds and copper coolers adapted to the application and the material. The machine is suitable for the primary forming of one or more metallic materials, so that monolithic and hybrid semi-finished products can are producible.

Technical Specification:

| Processable Casting Quantity and Casting Materials | approx. 70 kg heavy metals, aluminium and copper alloys |

| Melting/Holding Furnace | Induction, approx. 60 kW |

| Peeling Kinematics and Speeds | Go-Stop, Go-Stop-Back, continuous, high cycle, 0 mm/min - 1000 mm/min |

| Peeling Direction | Horizontal, inclined und vertical |

| Maximum Casting Geometry | Round shape (Ø 60 mm), strip cross-section (150 mm x 30 mm) |

Main Areas of Application:

- Monolithic continous casting of aluminium and copper alloys

- The continuous composite casting of aluminium and copper alloys

- Production of graded semi-finished products

Equipment:

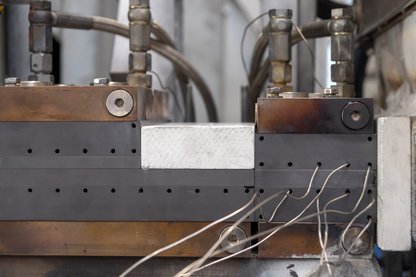

- Temperature measurement with thermocouples type K, class 1, recording frequency 1 Hz, 48 channels

- Mold temperature control with cooling water, four separate cooling water circuits, maximum flow rate approximately 10 l/min per channel, inlet temperature 13 °C to a maximum of 80 °C

-

Variable mold equipment based on stationary slide molds

Photo Gallery:

| Manufacturer | Loramendi |

| Model | SLC2-25L |

| Year of Production | 2014 |

Brief Description:

Core blowing describes a machine process in the foundry technology that produces organically or inorganically bound grains of sand. The molding material and the binder are shot into the core box by the sudden expansion in compressed air volume in less than a second and thereby compacted.

Technical Specification:

| Tool Dimensions | 750 mm x 960 mm x 560 mm |

| Shooting Head, Shooting Nozzels, and Sand Funnel are Water-cooled | |

| Tool Oil Heated | |

| Hot Air Fumigation |

Main Areas of Application:

- Production of inorganically bound sand grains

- Test specimen

- Water jacket cores

Equipment:

- A Tool manufactured by Aurrenak

- Modular design

- Module 1: 3-cylinder water jacket core (BMW)

- Module 2: bending bar, cyclinder, hot forming bar

Photo Gallery:

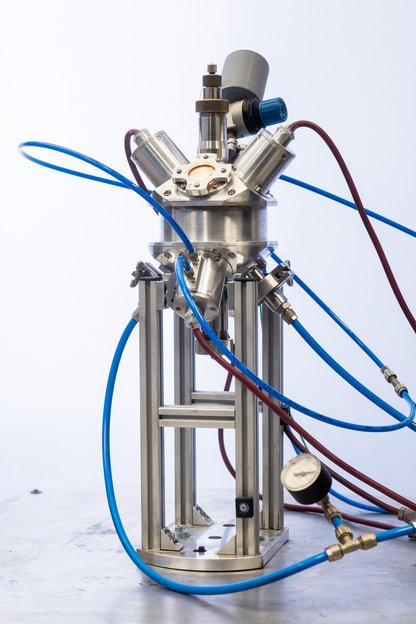

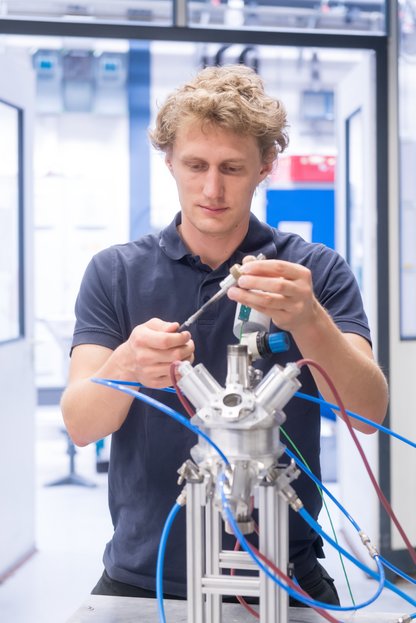

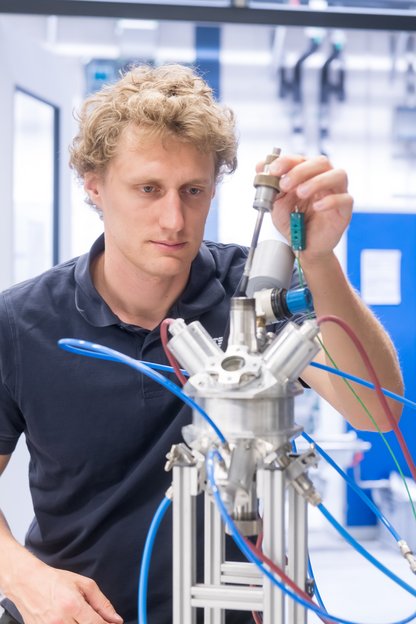

| Manufacturer | utg in-house design |

| Year of construction | 2022 |

Brief description:

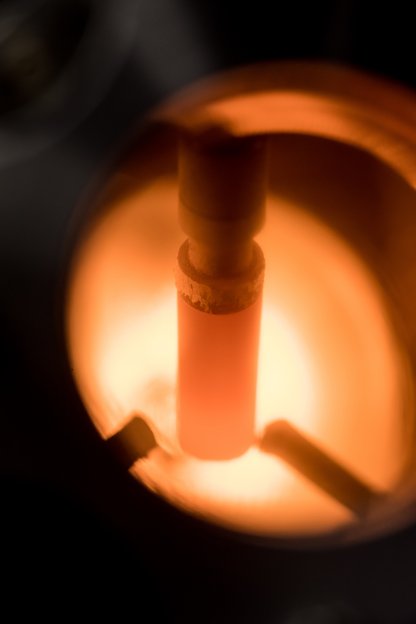

The analysis furnace was built as part of the DFG-funded project Development of a material model for gas generation in inorganic foundry sands. It enables the controlled heating of samples in a defined atmosphere (air, inert gas, or vacuum). Due to the modular design, numerous experiments can be carried out, such as the investigation of gas evolution and gas permeability of inorganically-bound molding materials or the heat treatment of ferrous materials. Using the analysis furnace makes it possible to carry out casting experiments on a laboratory scale and under laboratory conditions.

Technical Data:

| Maximum temperature | >2000 °C |

| Max. Heating rate | <1000 °C/s |

| Furnace chamber dimensions | 200 mm x 200 mm x 200 mm |

Main fields of application:

- Heat treatment of ferrous materials

- Investigation of gas evolution of inorganic molding materials

- Determination of gas permeability of inorganic molding materials

Equipment:

- 2 x induction heaters with 6 kW power each

- various inductor geometries

- Temperature measurement by means of thermocouples

- Flow and pressure-controlled protective gas flooding

- Vacuum pump

- Water cooled housing

References:

Kirchebner, B., Kammerloher, S., Fuchs, G., Reberger, E., Volk, W., & Lechner, P. (2023). A Test Stand for Quantifying the Core Gas Release and the Gas Permeability of Inorganically-Bound Foundry Cores. International Journal of Metalcasting, 1-9.

Pictures:

| Manufacturer | Forschungs-Neutronenquelle Heinz Maier-Leibnitz (FRMII) |

| Model | Halogen_10 |

| Year of Production | 2010 |

Brief Description:

The mirror furnace was developed to allow one to follow the processes in the material during heat treatment through neutron diffraction. For this purpose, samples get placed in the center of an aluminum sphere. These samples have a diameter of approximately 8 mm, and a length of roughly 15 mm. To not influence the neutron beam, focused light from four halogen lamps controls the temperature.

Using a graphite crucible melt material can also be studied, for example, solidification processes and diffusion on monolithic or bimetallic samples.

Technical Specifications:

| Maximum Temperature | 1200 °C |

| Maximum Rate of Heating | 50 °C/s |

| Specimen Dimensions | 8 mm x 15 mm |

Main Areas of Application:

- Material characterization (microstructure formation as a function of solidification rate or heat treatment)

- Composite formation (generation of bimetals under defined time-temperature processes)

Equipment:

- Temperature measurement through thermocouples (see temperature measurement)

Photo Gallery:

Brief Description:

The utg casting area has various melting and processing facilities. The melting equipment includes four resistance-heated furnaces (maximum temperatures 1000 °C, 750 °C, 1300 °C, and 1100 °C) and an induction furnace (output approx. 40 kW). In a single casting operation, metallic materials up to a mass of approx. 30 kg of heavy metal can be processed. The furnaces are suitable for melting and heat treatment purposes. The casting area has a hand-molding station in which casting molds are made from molding materials. The department has a large number of permanent molds. These permanent molds are adapted for different research projects and suitable for producing academic, abstracted geometries. The steel permanent molds tempering requires cooling water. A total of four separate cooling water circuits are available.

Technical Specifications:

| Melting and Heat Treatment Furnaces | Four resistance-heated furnaces and one induction furnace, up to 30 kg heavy metal, maximum temperature 1300 °C |

| Hand-Molding Station | Processing of molding sands into molds, maximum size approximately 100 cm x 60 cm in the mold parting plane |

| Cooling Water Tempering of Permanent Molds | Four separate circuits, maximum of 10 l/min per circuit, inlet temperature 13 °C - 80 °C |

Main Areas of Application:

- Production of metallic end products

- Development and qualification of novel measuring sensors

- The composite casting of serveral metallic materials

- Thermal analysis of metallic materials

- Casting defect prevention

&nbs

Equipment:

- Temperature measurement with thermocouples type K, class 1, measuring system NI 9213 from the manufacturer National Instruments, recording frequency max. 100 Hz, 64 channels

- Fiber optic strain sensors for in-situ measurement of solidification shrinkage and cooling strains

- Contactless IR temperature measurement

- Various molds made of hot work tool steel

- Stations for processing organic and inorganic molding materials