Cylindrical Gears

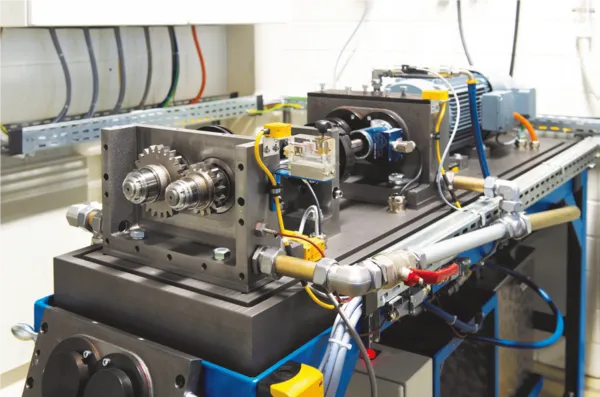

Cylindrical gears are the most common type of gear. The service life of cylindrical gears is limited by macro pitting, micro pitting, scuffing, wear, tooth root, or tooth flank fracture. The basis for the experimental research of these gear damages is the FZG back-to-back test rig, developed at the research center and used worldwide.

In this test rig concept, the test pinion and test wheel are fixed on two parallel shafts connected with the slave gear with the same transmission ratio. The decisive advantage of this bracing principle is that only relatively small powers of the drive machine are required, even for high test powers.

So it is possible to carry out very efficient an reliable tests on the types of damage described and lubricant and efficiency tests on external and internal gears with a module of 3 to 12 mm. With the FZG back-to-back test rigs, investigations can be carried out on gears with center distances of up to 200 mm or a module of up to 12 mm. Small gear test rigs can be used to perform tests on gears with a module of 0.3 to 1 mm, which are used, for example, in the fields of microsystems, robotics, and medical technology. More than 50 FZG back-to-back test rigs for cylindrical gears of different types are operating at the FZG.

Test rigs for experimental investigations on cylindrical gears:

- Standard FZG Cylindrical Gear Back-to-Back Gear Test Rigs (Center Distance 91.5 mm)

- FZG Cylindrical Gear Back-to-Back Gear Test Rigs (Center Distance 200 mm)

- Small Gear Test Rigs

- FZG Three Shaft Test Rig

- Load Spectra Test Rig

- Dynamic Test Rig

- Efficiency Test Rigs

- No-Load Power Loss Test Rig

- Internal Gear Test Rigs

- Back-to-Back Test Rig for Planetary Gears PGV01

- Hydraulic Pulsators

- Electromagnetic High Frequency Pulsators

- Mechanical Resonance Pulsator