Project Description

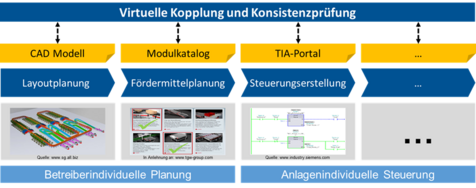

Digitization in modern automated material flow systems (aMFS) is advancing more and more in the context of Industry 4.0, bringing with it new and demanding challenges. Such systems' development is strongly characterized by close collaboration between actors from the disciplines of mechanics, electronics, computer science, and several departments such as development, sales, etc. The various actors use different design models and tools for the same project, each of which depicts sub-aspects relevant to the expert domain. Each of the actors has its view of the project, which is limited to a relevant model's aspects to solve its individual task. This enables focused and efficient processing of the tasks. However, since relevant aspects of different actors partly overlap or influence each other, it is currently common to model parts of a model again in an additional modeling tool. However, when changes are made during the development phase, this can lead to inconsistencies between the different models. Using automated material flow systems (aMFS) as an example, this research project will develop information technology methods and models that enable efficient, cross-domain collaboration. Therefore, a so-called virtual single underlying metamodel (V-SUMM) will be defined for aMFS to realize a continuous process chain during development, detect inconsistencies between development models at an early stage, and enable the reuse of development models across several areas and projects.

Project Partners

- Technical University of Munich, Chair of Materials Handling, Material Flow, Logistics

- University Duisburg-Essen, paluno

- Technical University of Munich, Institute of Automation and Information Systems