Pick and Place Unit (PPU)

Pick and Place Unit - Demonstrator for Evolution in Industrial Plant Automation

Update:

There has been a recent update to the PPU demonstrator: see below!

The challenge of long-living software

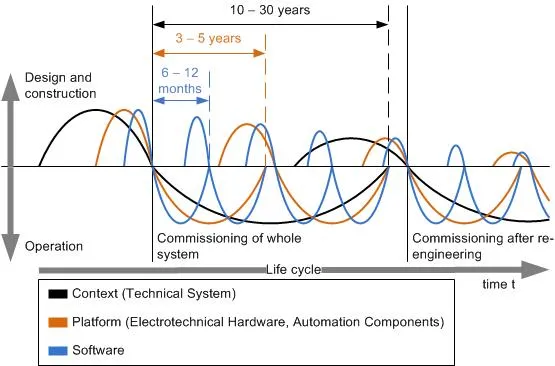

In machine and plant automation increasing complexity represents a growing challenge in its innovation processes. The different frequencies of innovation cycles and interconnectedness between disciplines complicate the understanding and handling of the evolution of a plant (cp. Fig. 1).

Motivation

Industrial plants are operated over long period of time. Hence, evolution of these plants is necessary to cope with technological developments or market requests. However, evolution cycles of disciplines involved in cooperative design of such plants are different. Therefore, further research needs to be done in order to provide an integrated variant and version management, i.e. evolution management, of such plants.

Evolution of the PPU

In order to enable the study of evolution in industrial plant automation, a set of 16 variants and versions of the PPU has been selected in cooperation with some projects conducting research on evolution. The evolution scenarios are characterized by a variety of different changes in platform, context and software. A description of the evolution scenarios is described in.

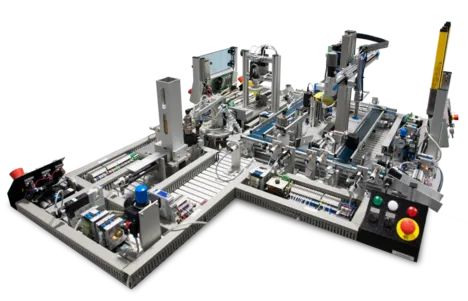

Description of the physical PPU

The compact demonstrator handles and manipulates work pieces of different material. The the PPU can detect different material and colors and can be controlled by many different kinds of control hardware. It perfectly keeps the balance between representing the reality and limiting the complexity and is therefore a useful evaluation plant for research in the automation domain.

Approaches to support long-living systems can be evaluated on this plant. To provide use-cases and allow the comparison of different solutions, 16 evolution scenarios have been developed by the research group at AIS.

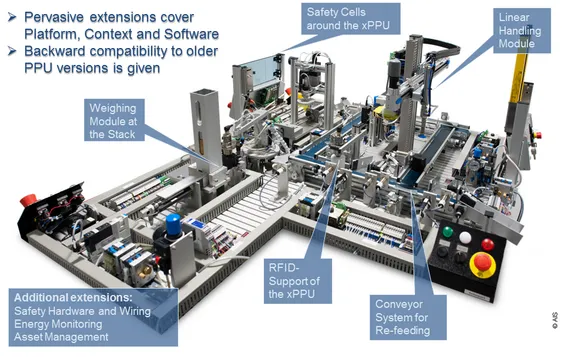

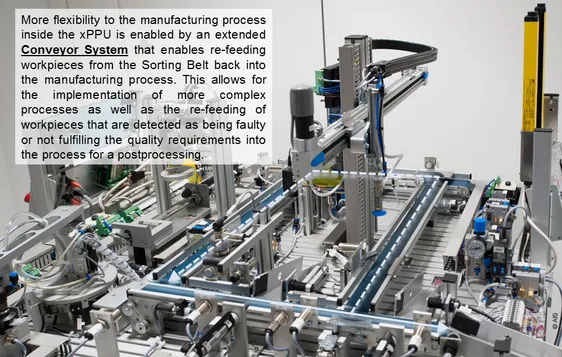

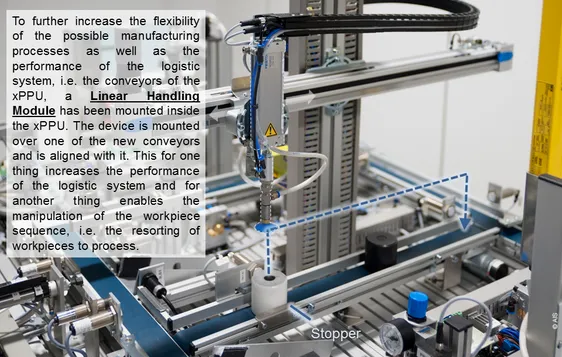

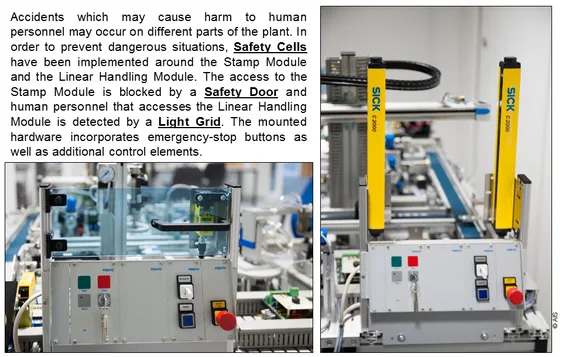

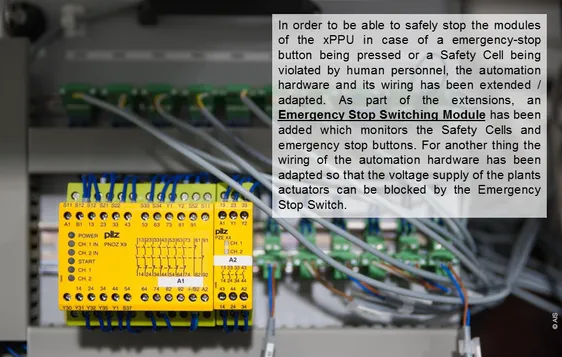

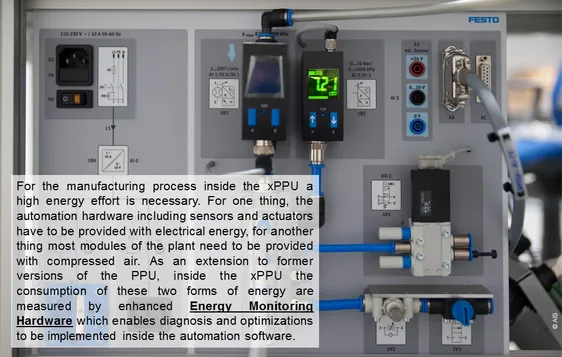

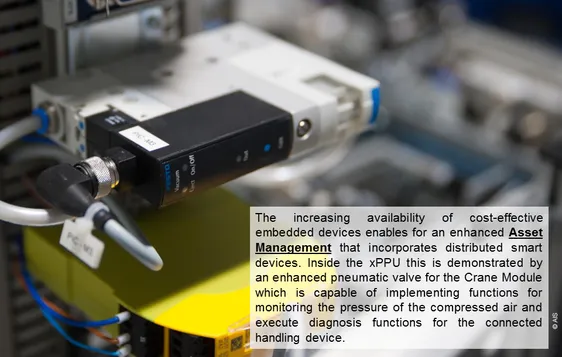

Recent Updates to the PPU Demonstrator: Novel Features of the Extended Pick&Place Unit (xPPU)

Available documentations for studying evolution

To make research in many different areas possible, a detailed documentation, models and control code have been developed and provided:

- SysML models (one model for each scenario) with evolutionary changes in behavior and structure

- CAD models of the PPU in each evolution step

- Technical documentation like drawings or circuit diagrams

- PLC implementations of each evolution scenario in classical IEC 61131-3 languages as well as implementations based on state charts in plcUML, an alternative way to implement PLC software.

- Simulation in MatLab of each of the evolution scenarios of the PPU

The SysML models of almost each scenario can be downloaded for free. Please notice our license terms.

The models have been created in the open source tool Papyrus, for opening and modifying the models you need to install Papyrus.

IEC 61131-3 implementation is accessible in github: Link .

Publications

- Vogel-Heuser, B.; Bougouffa, S.; Sollfrank, M.: Researching Evolution in Industrial Plant Automation: Scenarios and Documentation of the extended Pick and Place Unit. Technical Report No. TUM-AIS-TR-02-18-06, Online available: mediatum.ub.tum.de/node, 2018.

- Vogel-Heuser, B.; Fuchs, J.; Feldmann, S.; Legat, C.: Interdisciplinary Product Line Approach to Increase Reuse (Interdisziplinärer Produktlinienansatz zur Steigerung der Wiederverwendung). In: Automatisierungstechnik, Vol. 63, No. 2, pp. 99-110, 2015.

- Feldmann, S.; Legat, C.; Vogel-Heuser, B.: Engineering Support in the Machine and Plant Manufacturing Domain through Interdisciplinary Product Lines: An Applicability Analysis. In: 15th IFAC Symposium on Information Control in Manufacturing (INCOM), Ottawa, Canada, 2015.

- Vogel-Heuser, B.; Feldmann, S.; Folmer, J.; Kowal, M.; Schaefer, I.; Ladiges, J.; Fay, A.; Haubeck, C.; Lamersdorf, W.; Lity, S.; Kehrer, T.; Tichy, M.; Getir, S.; Ulbrich, M.; Klebanov, V.; Beckert, B.: Selected Challenges of Software Evolution for Automated Production Systems. In: 13th IEEE International Conference on Industrial Informatics (INDIN), Cambridge, UK, 2015

- Vogel-Heuser, B.; Folmer, J.; Legat, C.: Anforderungen an die Softwareevolution in der Automatisierung des Maschinen- und Anlagenbaus. In: Automatisierungstechnik (at), Vol. 62, No. 3, 2014, S. 163-174.

- Vogel-Heuser, B.; Legat, C.; Folmer, J.; Feldmann, S.: Researching Evolution in Industrial Plant Automation: Scenarios and Documentation of the Pick and Place Unit. Technical Report No. TUM-AIS-TR-01-14-02, Online available: mediatum.ub.tum.de/node, 2014.

- Vogel-Heuser, B.; Legat, C.; Folmer, J.; Rösch, S.: Challenges of Parallel Evolution in Production Automation Focusing on Requirements Specification and Fault Handling. In: Automatisierungstechnik (at), Vol. 62, No. 11, 2014, S. 755-826.

- Legat, C.; Folmer, J.; Vogel-Heuser, B.: Evolution in Industrial Plant Automation: A Case Study. In: 39th Annual Conference of the IEEE Industrial Electronics Society (IECON), Vienna, 2013, S. 4386 - 4391.

- Li, F.; Bayrak, G.; Kernschmidt, K.; Vogel-Heuser, B.: Specification of the Requirements to Support Information Technology-Cycles in the Machine and Plant Manufacturing Industry. In: 14th IFAC Symposium on Information Control Problems in Manufacturing (INCOM'12), Bukarest, 2012, S. 1077-1082.